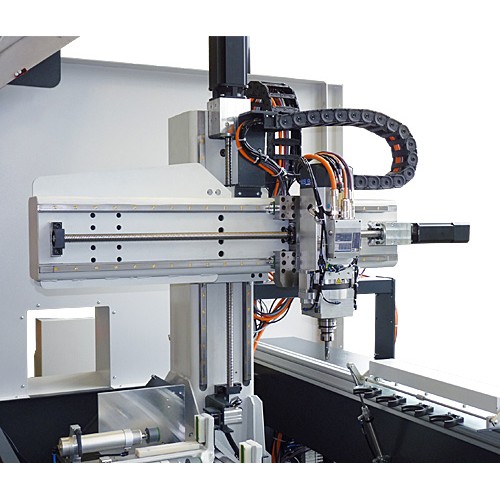

3-axis model for metal construction applications

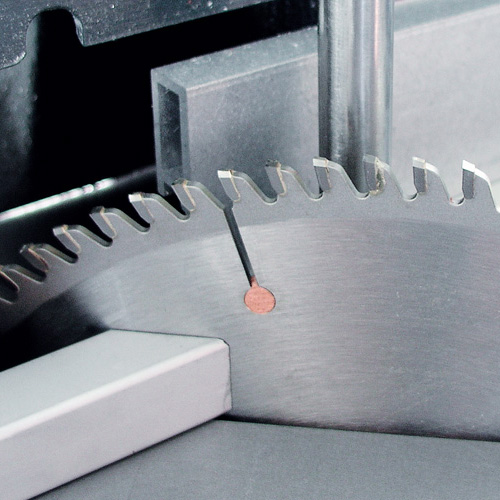

- Designed for economical and efficient machining of aluminium, PVC and steel profiles

- All operations, such as routing, drilling and tapping are performed while the profile bar is stationary to protect the profile surfaces

- A rotation unit (rotating mechanism) integrated into the spindle makes it possible to adjust the rotating angle head to 0°, -90°, -180° and -270°

- Better machining results thanks to the intelligent control technology

- Fast positioning of the machining unit with up to 120 m/min thanks to dynamic servo drives

- Tapping without compensation chuck

- Automatic clamp recognition and clamp positioning

- Automatic tool changer with four tool tray positions (without tools)

- Automatic tool changer for an angle head

- Modern 3-axis controller

- The absolute rotary encoder system means no axis homing is required

- Automatic clamp recognition and positioning prevents collisions

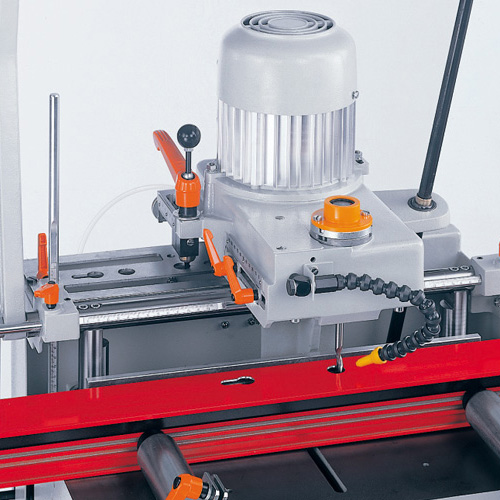

- Power torque routing motor with enclosed speed control for short spindle start-up and braking times.

- Certified, drive-integrated safety functions

- Low power consumption thanks to the intelligent control technology

- DC link coupling in the axis drives with power feedback and brake energy buffering in the drives ensure energy recovery

- Green Line cooling unit for the control cabinet with reduced energy consumption.

- Windows operating system

- 15″ flat screen display, USB ports and network connection

- Simple, stress-free program entry with eluCam on the operating panel, even during operation

- Remote maintenance via TCP/IP using existing Internet connection

Machine configuration

- Air-cooled 8 kW, S1 routing spindle

- Enclosure to protect the operator

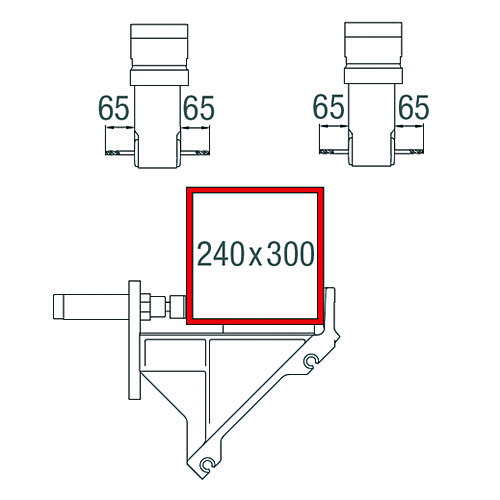

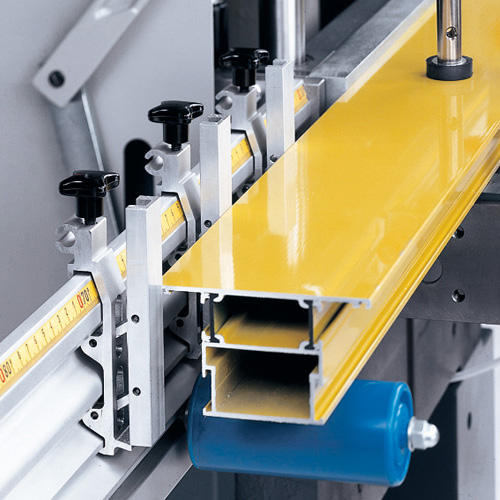

- Four horizontal, pneumatic material clamping units

- A material stop on the left

- Tool holder HSK-F63

- Routing spindle with integrated rotation unit (0°, -90°, -180° and -270°) for

- Angle head

- HSK-F63 rotating angle head for two tools

- Swarf trays for swarf removal

- Minimum-volume lubrication system

- High performance cutting fluid

- Hand-held operator terminal

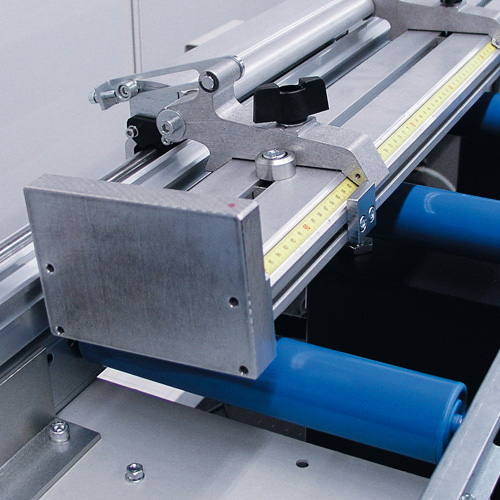

- Depth gauge

Technical specifications

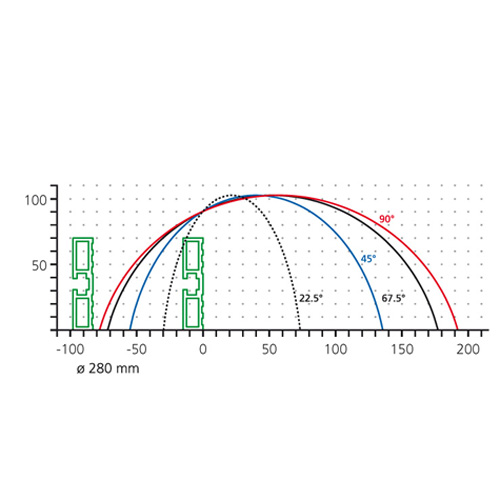

- Max. machining length without profile end machining, 4,150 mm

- Max. machining length with profile end machining, 4,000 mm

- Traverse path X-axis 4,295 mm, Vmax. 120 m/min.

- Traverse path Y-axis 910 mm, Vmax. 60 m/min.

- Traverse path Z-axis 475 mm, Vmax. 60 m/min.

- Direction of machining 5 (above, behind, front, left, right)

- Positioning accuracy +/- 0.1 mm

- Max. spindle speed 24,000 rpm

- Spindle power output 8 kW, S1 with feedback (air-cooled)

- Tool holder HSK – F63

- Automatic tool changing

- Four (max. 16) tool tray positions in the automatic magazine

- Angle head

- Disc milling cutter diameter 120 mm

- Tool length (from extent of taper) max. 150 mm

- Clamp positioning automatic

- Clamp Basic (with round guides)

- eluCam software

- Compressed air supply > 7 bar

- Power supply 400 V, 3~, 50 Hz, 22 A

- Air consumption per minute approx. 185 l with spraying

- Total length 6,739 mm

- Depth 2,180 mm

- Height 2,800 mm

- Weight Approx. 2,865 kg

Options

- Tools

- Tool holders

- Automatic tool changer for standard tools

- Automatic tool changer for angle head

- Length measurement on both sides

- Additional stop for overlength machining (left)

- Green Line cooling unit for the control cabinet

- Barcode scanner

- Protective enclosure can optionally completely enclose the machine on all sides, with additional sound insulation

- Easy and intuitive operation thanks to the modern elumatec Customer Interface (ECI)

- Stationary tool magazine

- Four clamps as standard. Up to eight clamps can be equipped as an option

- Material reference stop (right) for positioning workpieces with overlength machining

- Double clamping and other accessories on request