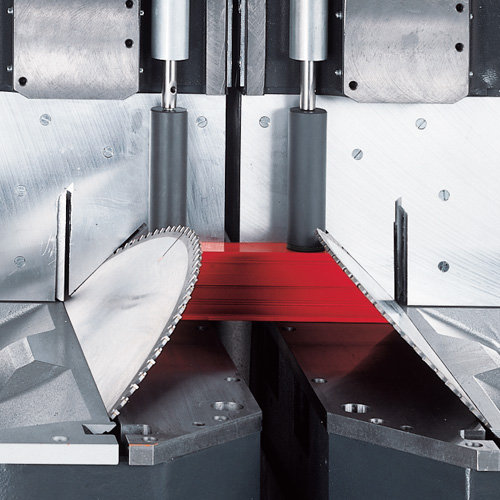

Designed for economical and efficient machining of aluminium, PVC and steel profiles

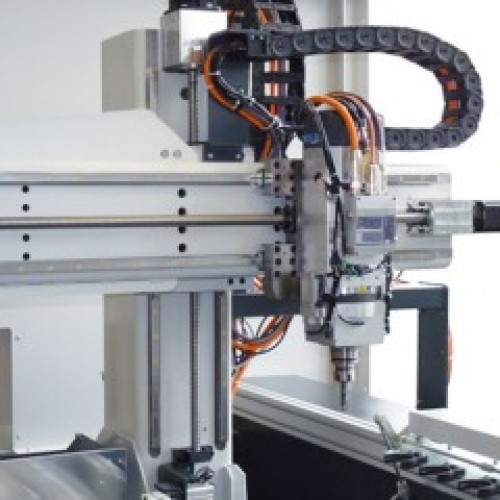

All operations, such as routing, drilling and tapping, are performed while the profile bar is stationary to protect the profile surfaces

Better machining results thanks to the intelligent control technology

Fast positioning of the machining unit with up to 60 m/min thanks to dynamic servo drives

Tapping without compensation chuck

Automatic clamp recognition and clamp positioning

Automatic tool changer with four tool tray positions (without tools)

Modern 3-axis controller

The absolute rotary encoder system means no axis homing is required

Automatic clamp recognition and positioning prevents collisions

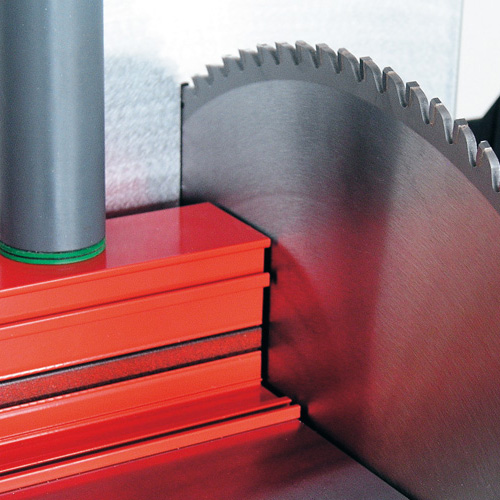

Power torque routing motor with enclosed speed control for short spindle start-up and braking times.

Certified, drive-integrated safety functions

Low power consumption thanks to the intelligent control technology

DC link coupling in the axis drives for greater energy efficiency

Windows operating system

15″ flat screen display, USB ports and network connection

Simple, stress-free program entry with eluCam on the operating panel, even during operation

Remote maintenance via TCP/IP using existing Internet connection

Machine configuration

Air-cooled 8 kW, S1 routing spindle

Enclosure to protect the operator

Four horizontal, pneumatic material clamping units

A material stop on the left

Tool holder HSK-F63

Minimum-volume lubrication system

High performance cutting fluid

Hand-held operator terminal

Depth gauge

Options

Uninterruptible power supply (UPS)

Tools

Tool holders

Automatic tool changer for max. four standard tools

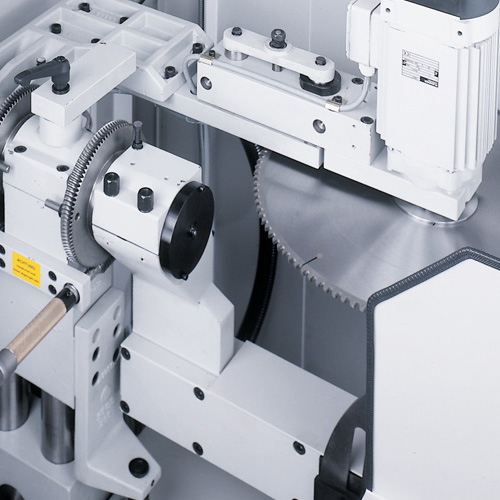

Automatic tool changer for angle head

HSK-F63 rotating angle head for two tools

Length measurement on both sides

Additional stop for overlength machining (left)

Swarf trays for swarf removal

Green Line cooling unit for the control cabinet with reduced energy consumption

Barcode scanner

Protective enclosure can optionally completely enclose the machine on all sides, with additional sound insulation

Easy and intuitive operation thanks to the modern elumatec Customer Interface (ECI)

Four clamps as standard. Can be equipped with up to eight clamps

Material reference stop (right) for positioning workpieces with overlength machining

Double clamping and other accessories on request

SBZ 122/70 plus

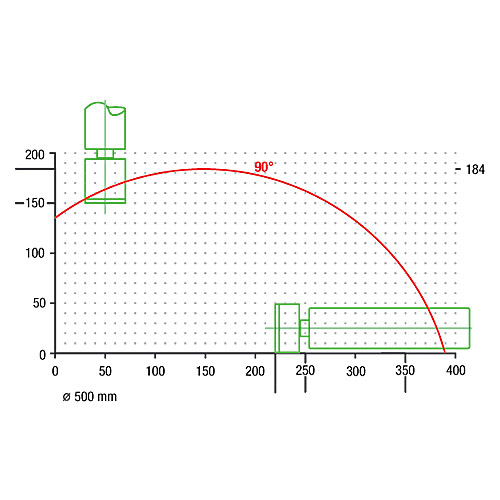

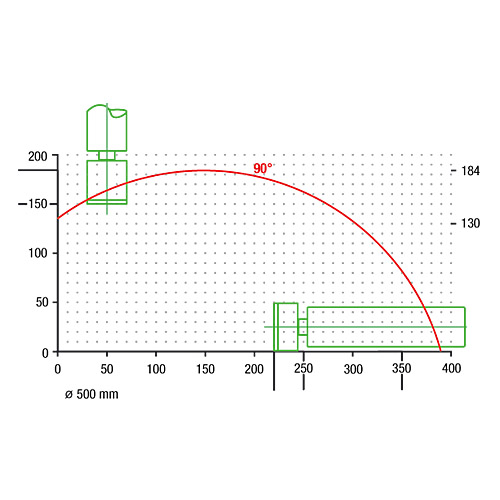

Max. machining length without profile end machining 4150 mm

Max. machining length with profile end machining 4000 mm (optional)

Traverse path X-axis 4295 mm, Vmax. 60 m/min.

Traverse path Y-axis 910 mm, Vmax. 45 m/min.

Traverse path Z-axis 475 mm, Vmax. 45 m/min.

Direction of machining 1 (from above), (5 optional)

Positioning accuracy +/- 0.1 mm

Routing spindle speed max. 24,000 rpm

Routing spindle power 8 kW, S1 with feedback (air-cooled)

Tool holder HSK-F63

Tool changing automatic

Tool tray positions in the automatic magazine 4 (max. 16)

Angle head Optional

Disc milling cutter diameter 100 mm

Tool length (from extent of taper) max. 150 mm

Clamp positioning automatic

Clamps Basic (with round guides)

Software eluCam

Compressed air supply > 7 bar

Power supply 400 V, 3~, 50 Hz, 25 A

Air consumption per minute approx. 185 l with spraying

Total length 6739 mm

Depth 2180 mm

Height 2810 mm

Weight approx. 2900 kg