Description

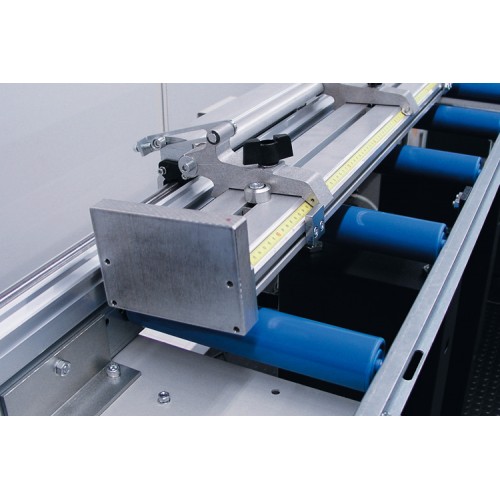

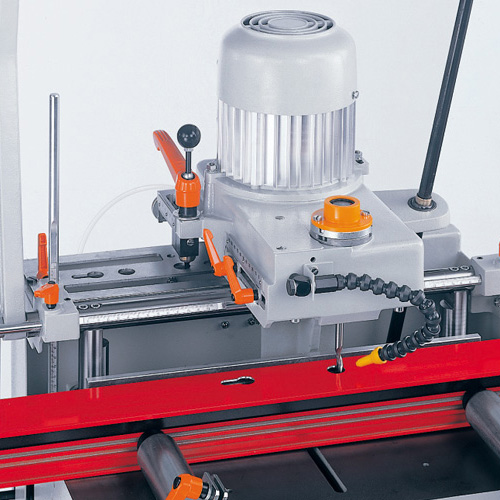

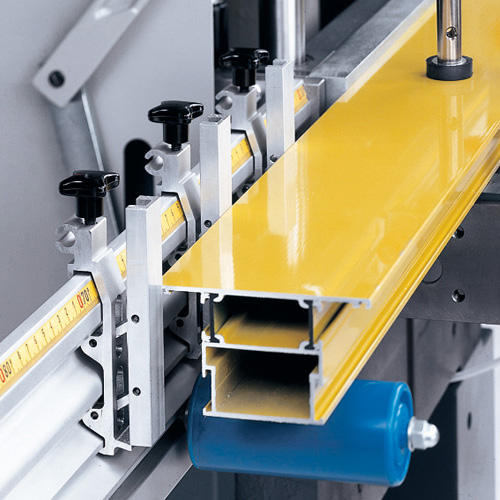

- The handle drilling unit with a 3-spindle boring head and automatic feed makes it possible to machine in two planes without re-clamping the material. The height of this unit can be adjusted

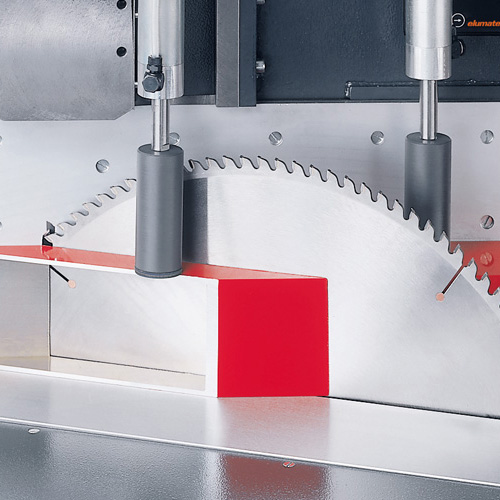

- Door machining is possible

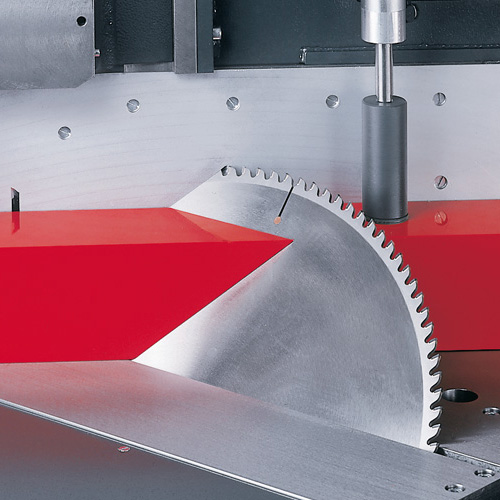

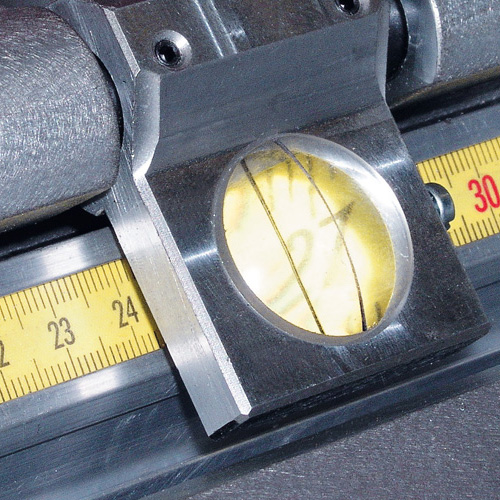

- Copy routing using side stops or templates at a ratio of 1:1

- Pneumatic tracer point with two levels for two different cutter diameters

- The “Spindle Lock” feature makes tool changing easy

- Pneumatic material clamping unit

Technical specifications

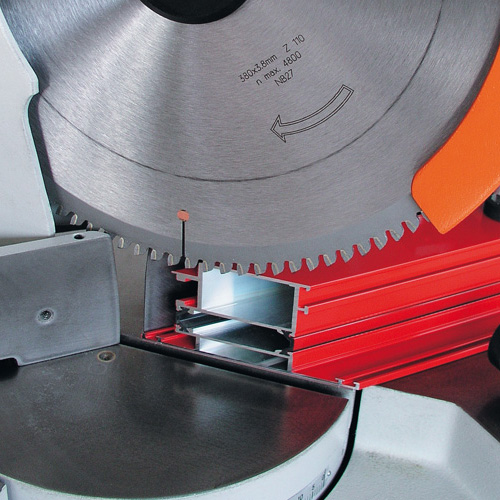

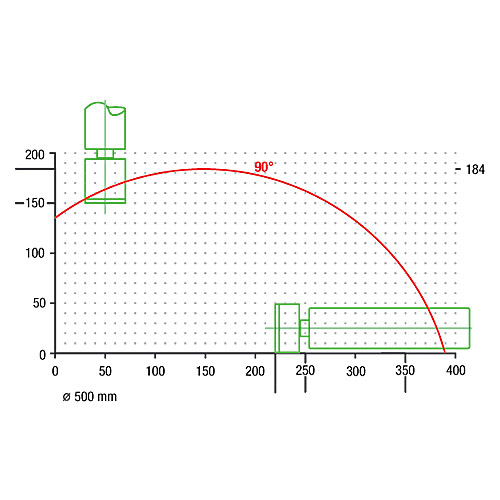

- Horizontal cutting range using a stop 300 x 120 mm

- Horizontal cutting range using a copy template 285 x 110 mm

- Clamping range for profiles, with drilling unit 150 x 130 mm

- Travel 105 mm

- Power supply 230/400 V, 3~, 50 Hz

- Router motor power output 0.74 kW

- Spindle speed 12,000 rpm

- Drill motor power output 1.05 kW

- Drill spindle speed 750 rpm

- Compressed air supply 7 bar

- Air consumption per working cycle 12 l

- Length 780 mm, depth 930 mm, height 1,545 mm, weight 230 kg

Options

- GF 171/10 with centring unit for a centered handle position

- GF 171/11 with right and left stop system for a consistent handle position

- Additional pneumatic tracer points (for optimal utilisation of the template)

- Hydro-pneumatic feed with rapid mode

- Collets

- Special material clamping units

- Stop systems

- Routing and drilling tools