Description

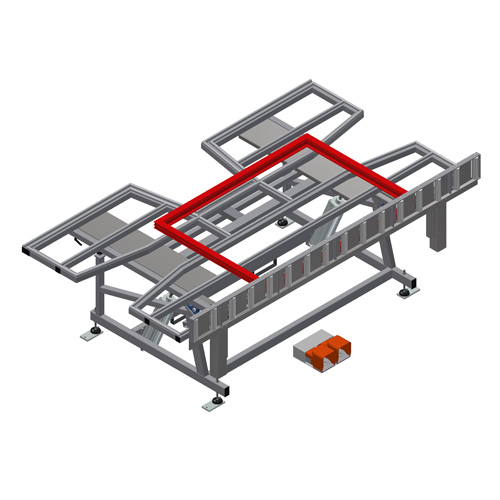

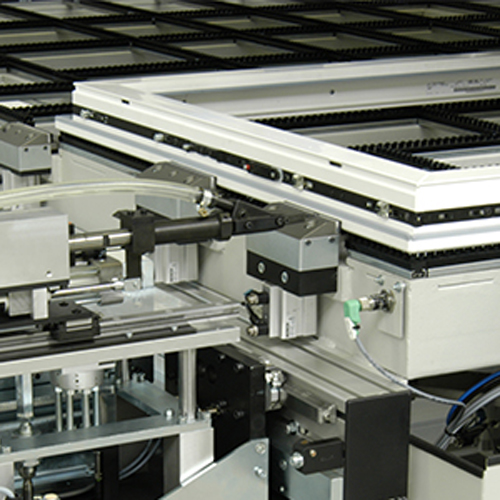

- Two highly-dynamic electric screw driving units

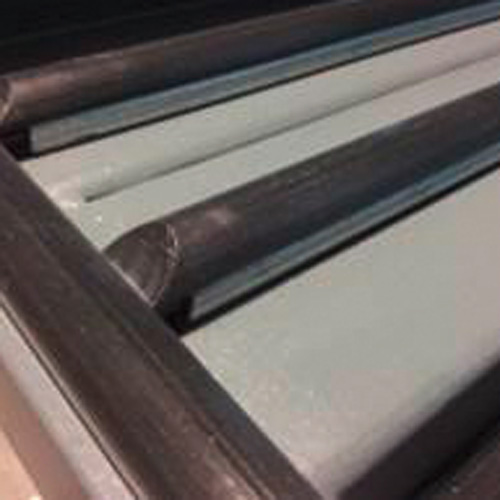

- Processing of up to eight different Euro groove heights – independently of the profile and hardware system

- Maximum processing quantity through the use of highly dynamic modules and intelligent control technology

- Gentle screw placement in the sash hinges

- Operation of the information management system is intuitive and offers a visualisation of all hardware data, a diagnostics and reporting tool and maintenance management as well as other options

- The integrated remote maintenance feature avoids on-site visits of service technicians

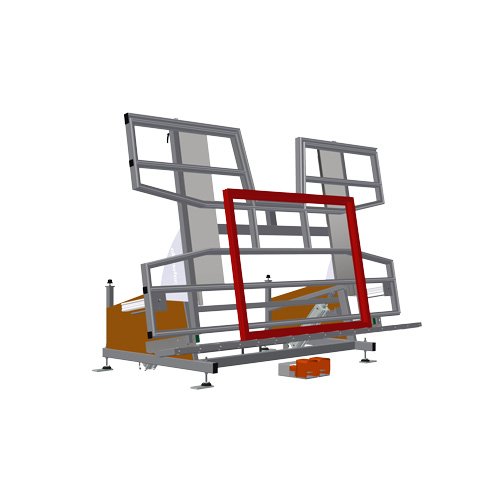

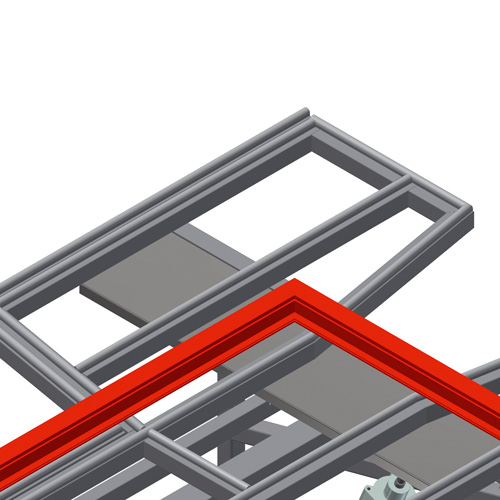

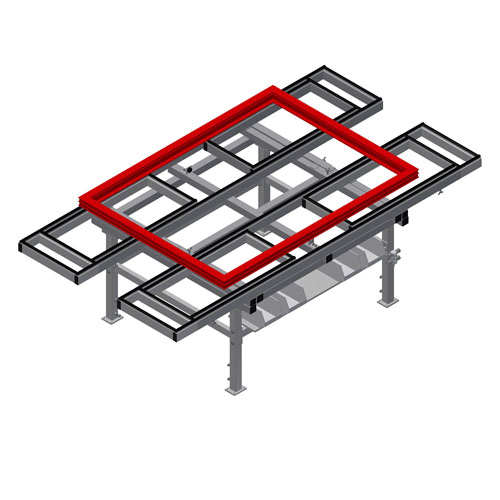

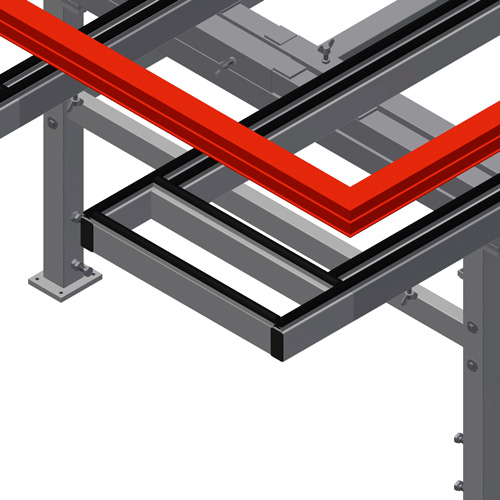

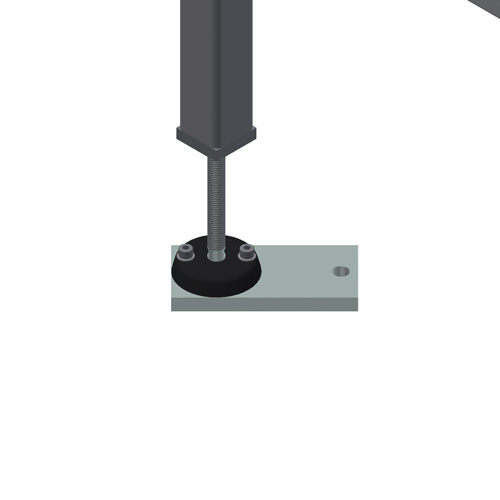

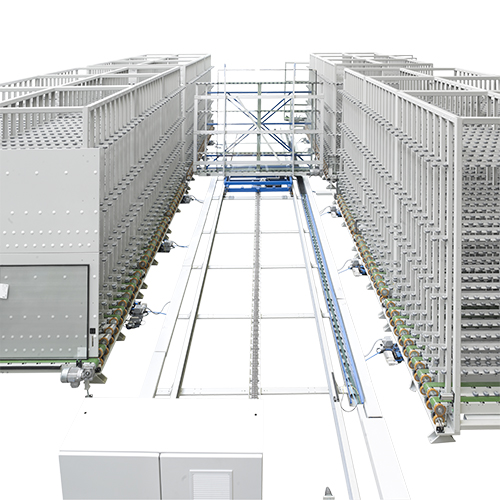

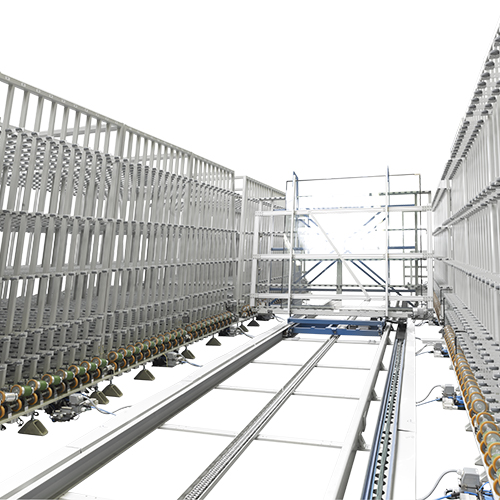

- Suitable for integration in a production line

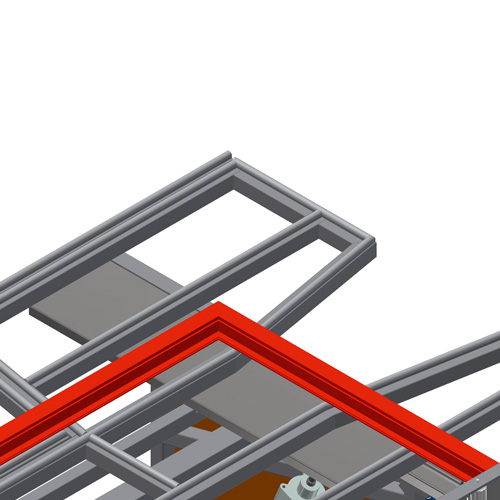

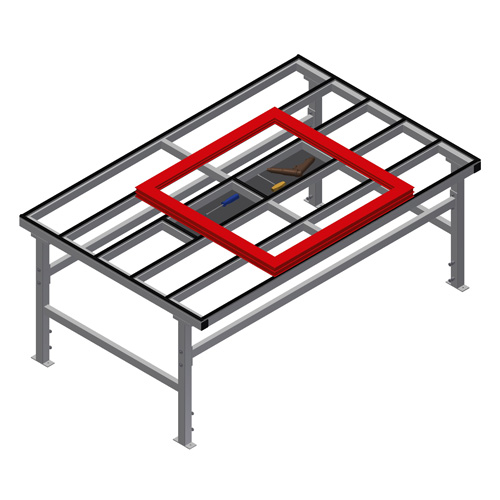

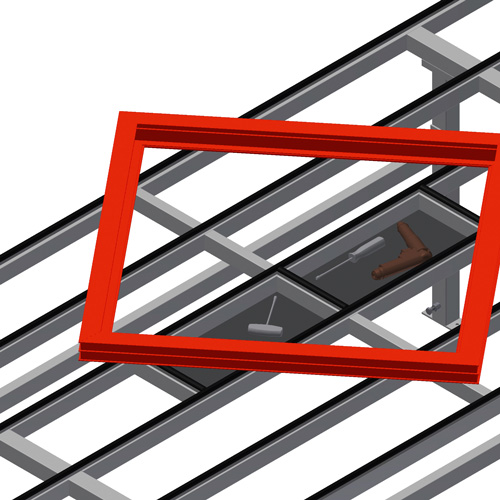

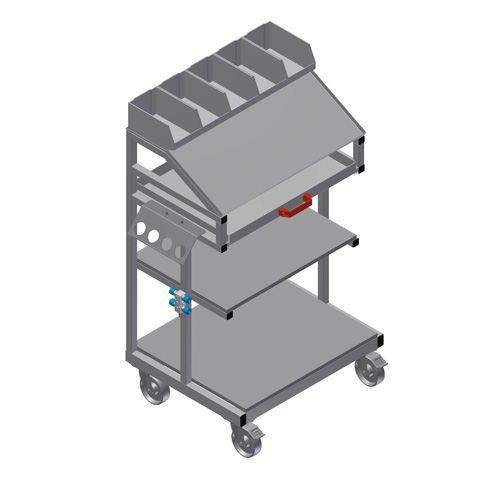

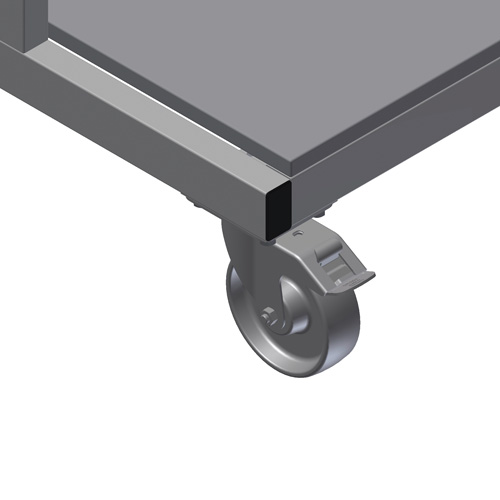

- Hardware pre-mounting table with compartments for long hardware components and corner linkage gears

- To ensure a continuous material flow in the production process, the sash scissor stay is folded into place via a clamping arm

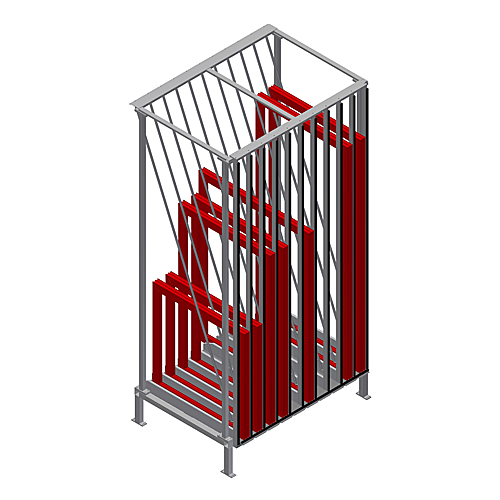

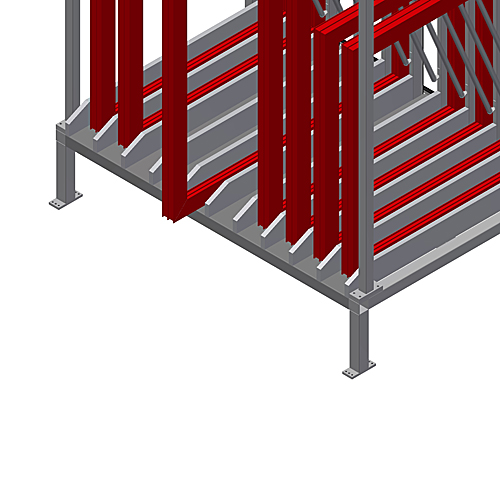

- After completion of screw placement, the sashes are automatically sorted and transferred to a vertical buffer rack

Technical specifications

- Min. depth, 60 mm

- Max. depth, 100 mm (incl. mullion profile)

- Min. facing width, 69 mm (for mullion profile of 49 mm)

- Max. facing width, 130 mm (150 mm incl. mullion profile)

- Min. Euro groove height, 30 mm

- Max. Euro groove height, 50 mm

- Min. sash rebate width, 320 mm

- Max. sash rebate width, 1,600 mm (incl. mullion profile)

- Min. sash rebate height, 320 mm

- Max. sash rebate height, 2,600 mm

- Min. sash glazing rebate width, 220 mm

- Min. sash glazing rebate height, 220 mm

- Max. sash weight, 100 kg

- Cycle time < 1.5 minutes (depending on the type of hardware)

- Profile systems: PVC / PVC steel reinforced, profiles / composites

Options

- Automatic stacking

- Sash hinge drilling

- Corner hinge screw driving

- Scissor stay closing function