Description

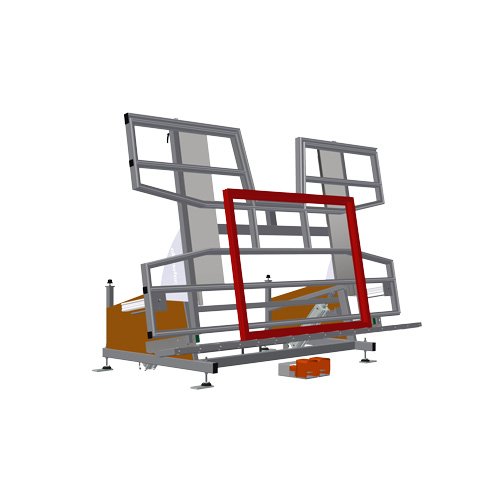

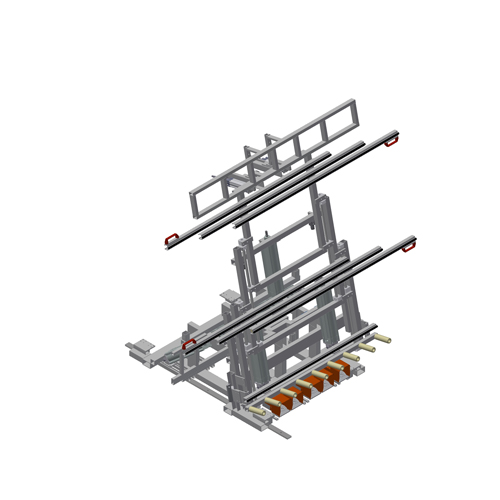

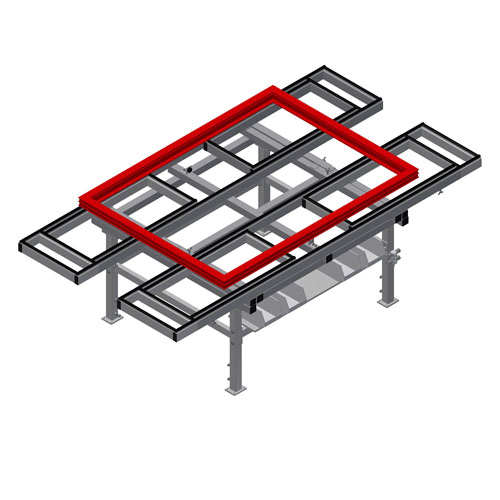

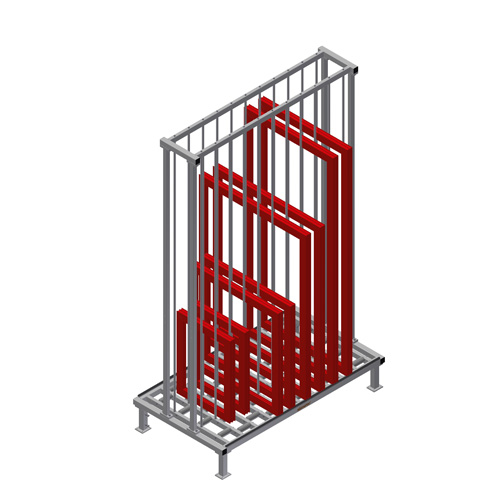

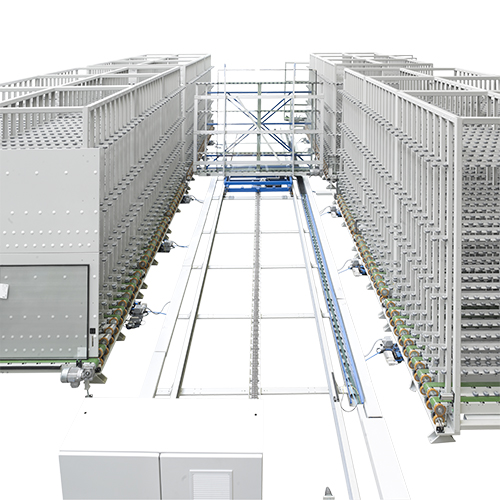

- The innovative and highly efficient hardware drilling and screw driving station for frame hinges and pivots

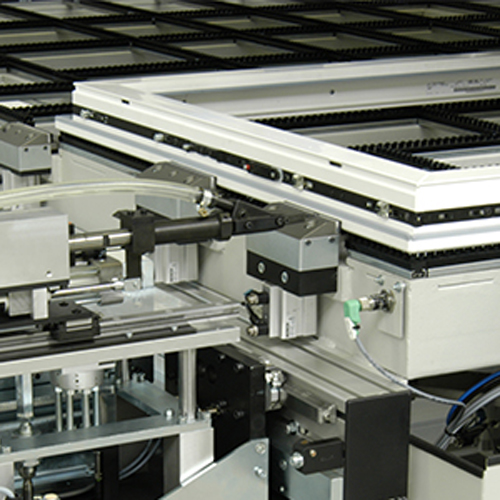

- Work quickly and accurately – this machine enables an amazing productivity boost in window manufacturing

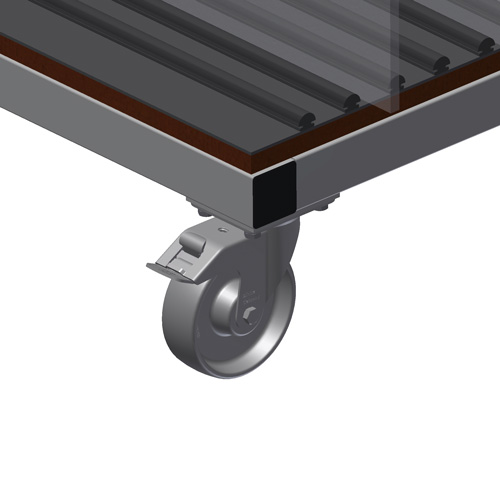

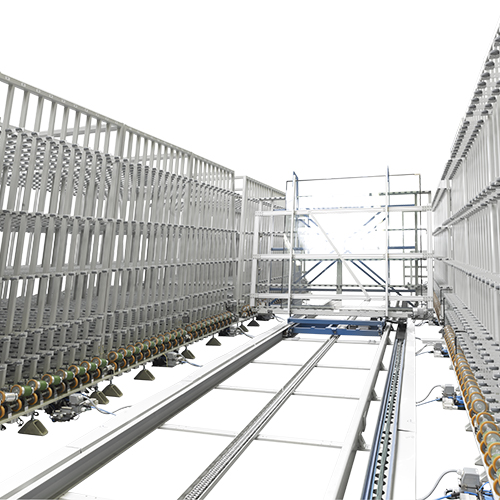

- Thanks to the easy handling and ergonomically designed work sequence, drilling, assembly, and screwing of the tilt/turn hinges can be performed by a single operator.

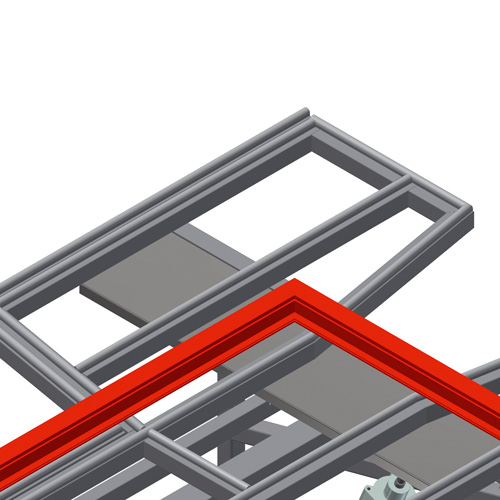

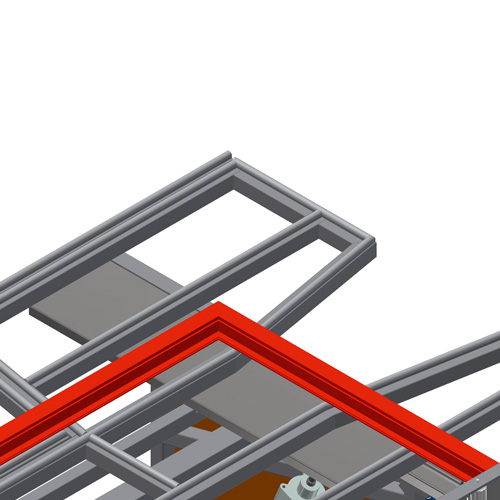

- Due to the movable stop system, the time-consuming drilling of locating and screw holes with a template can be omitted

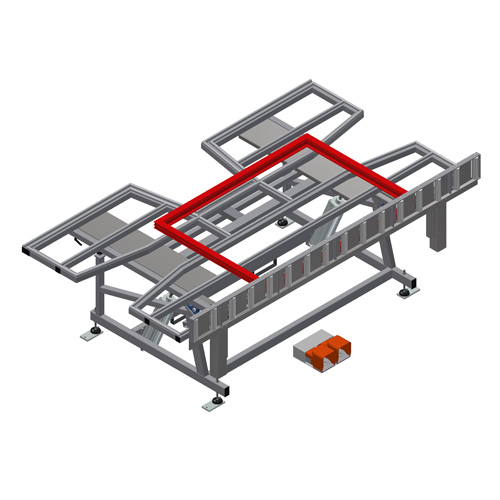

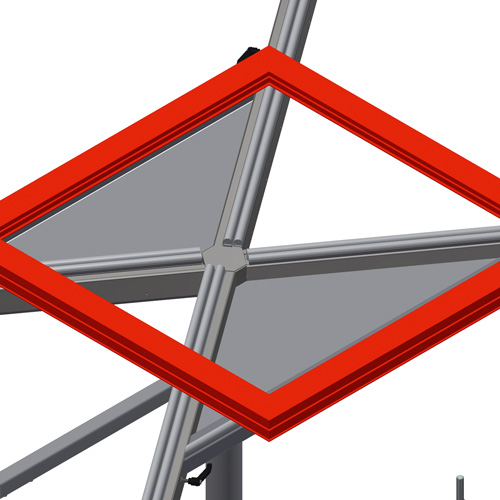

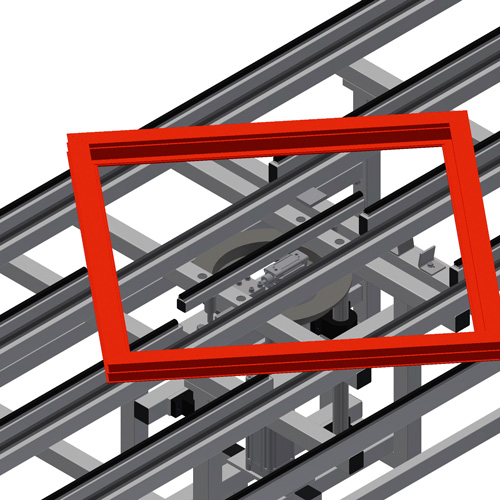

- The unit can be rotated by 90° for machining multi-sash frames

- The adjusting device can be positioned in the Y-direction using grid dimensions for drilling pivot bolts into multi-sash frames.

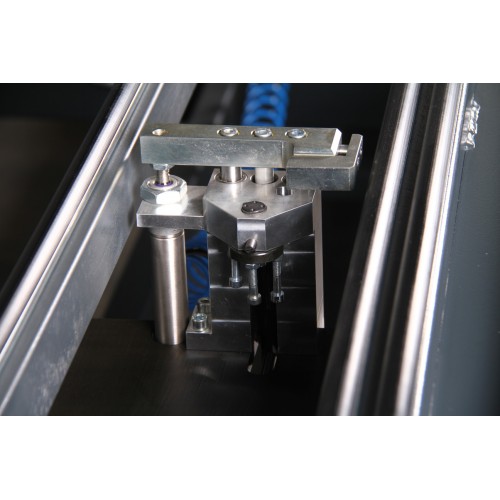

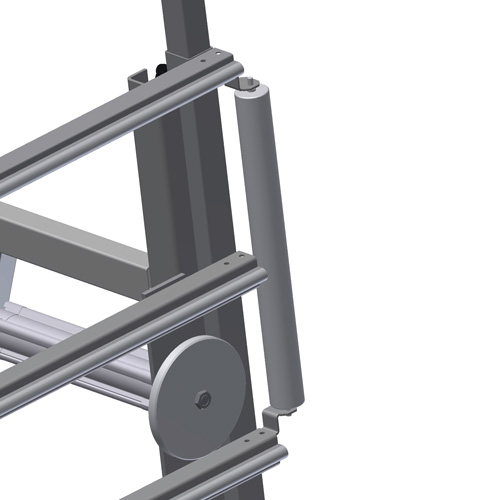

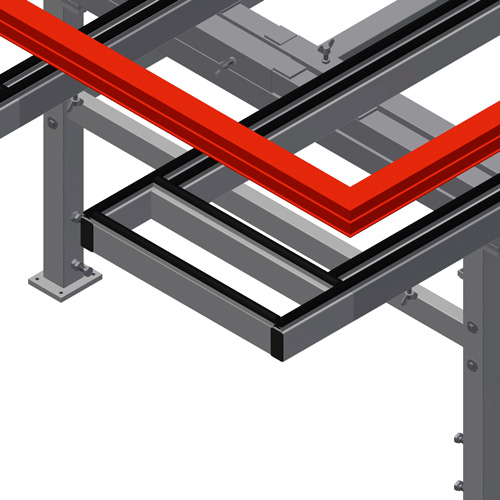

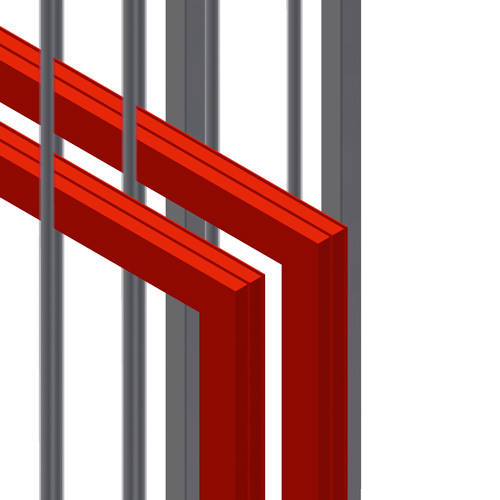

- The hinges and pivots are screwed to the closed frame by the vertical screwing feed unit which is manually moveable on moving carrier plates.

- The unit is equipped with an automatic screw infeed, a screwdriver turbine for screwing self drilling screws, and a pneumatic screwing depth stop

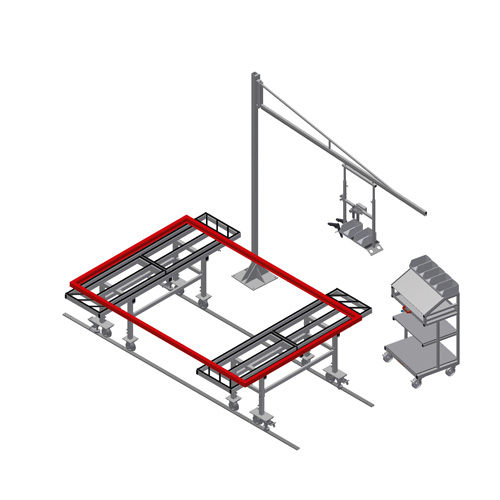

- Pneumatic frame clamping and positioning device can be moved beyond table centre

- Frame rebate dimensions from 360 to 3,400 mm

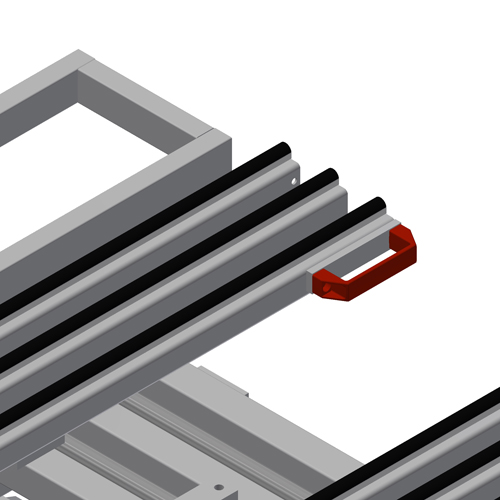

- Two pneumatically lowerable rebate stops with revolver for up to four different frame depths

- Laser unit shows the screw driving position

Technical specifications

- Table length 4,040 mm

- Table width 1,700 mm

- Total length 4,220 mm

- Total width 2,010 mm

- Height 1,720 mm

- Table height adjustable 950 – 1,050 mm

- Frame dimension min. 560 x 200 mm

- Frame dimension max. 3,800 x 1,700 mm

- Min. profile height 54 mm

- Max. profile height 110 mm

- Weight 650 kg

- Compressed air supply 7 bar

- Air consumption:

- Screw driving unit approx. 250 l/min.

- Clamping unit approx. 40 l/min.

- Screw dimensions:

- Head diameters 5.0 – 9.0 mm

- Shank diameters 3.5 – 4.5 mm

- Length approx. 10.0 – 35.0 mm

- Power supply 230/400 V, 3~, 50 Hz

- Motor power of 1.1 kW at 2,825 rpm