Description

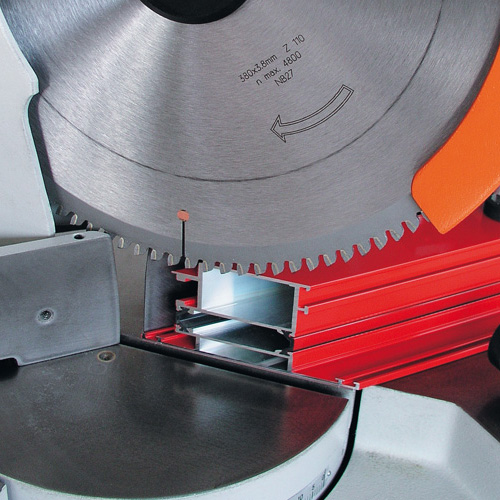

For machining transoms and door profiles made of aluminium or PVC

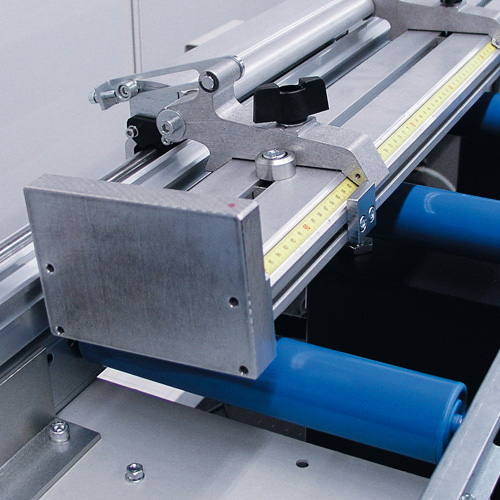

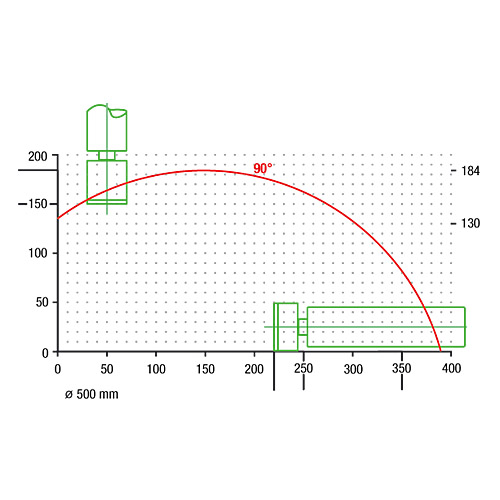

Large cutting range of up to 400 mm

Continuously adjustable table height

Manual feed of the routing unit

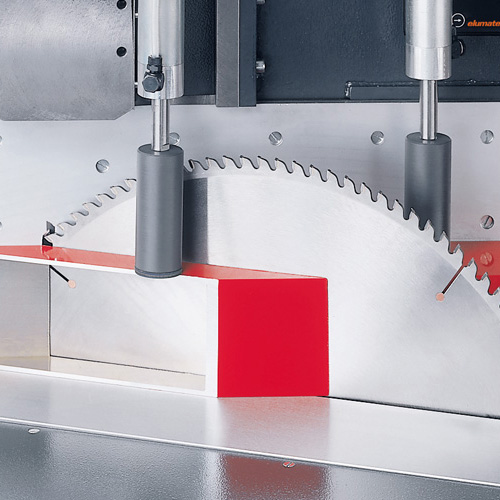

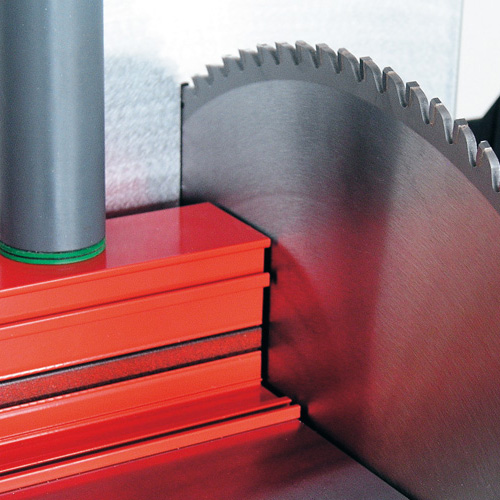

Tool diameters of up to 280 mm can be used

The material stop can be pivoted up to 70° to the left and right. Notching up to 30° (acute angles, left and right). Detent at 90° with index pin.

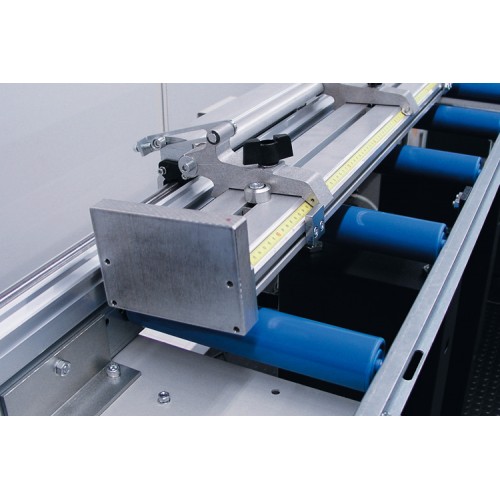

Two installation positions for the material stop

With quick tool change system and “Spindle Lock” for easy tool changing

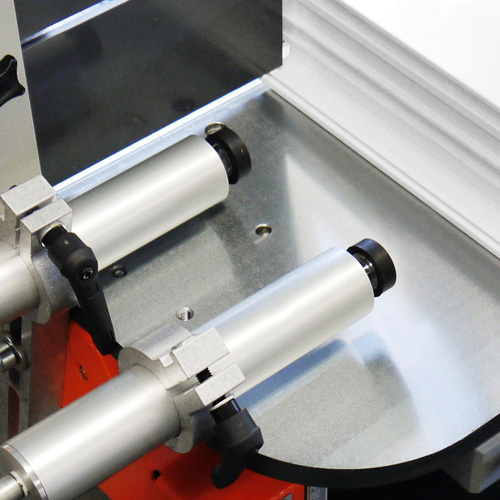

Precise, smooth-action and low-wear recirculating ball guides

Horizontal and vertical pneumatic material clamping provides flexibility

Depth stop for four different notching depths

Integrated connecting piece with extractor hose for connection to an extraction system

Pulsed coolant system

Technical specifications

Cutting tool diameter max. 280 mm

Cutter bore 40 mm

Max. profile height 165 mm

Cutting height 145 mm

Cutting depth 110 mm

Cutting length 400 mm

Spindle speed 2,800 rpm

Travel 550 mm

2.5 kW of power at 400 V / 50 Hz

Compressed air supply 7 bar

Power output 2 kW

Air consumption 10 l per working cycle, 20 l with minimum-volume lubrication system

Length 1,540 mm, depth 905 mm, height 1,000 mm, weight 248 kg

Options

Extraction system

4-fold turret stop for table height

Digital display

Cutting tools

High performance cutting fluid