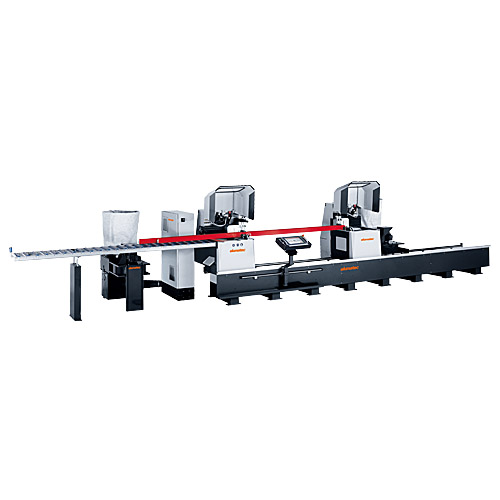

A fast downstream centre for reinforcement screw driving, drilling and routing cut-to-length profiles for window, door and curtain wall manufacturing with and without steel reinforcement.

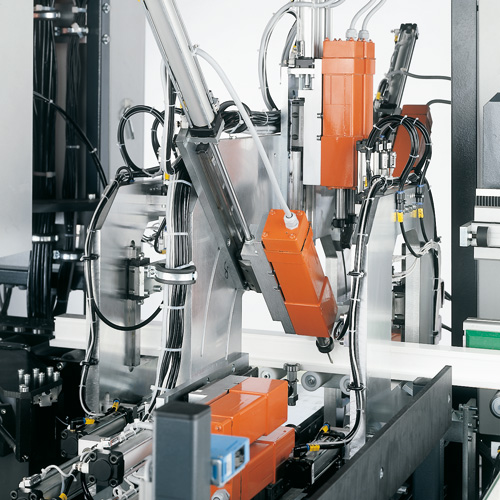

Portal design for high profile cross-sections and process-optimised throughput. Additional efficiency through parallel processing by external reinforcement screwdriver system.

- Work sequence as needed, either from the left towards the right or the reverse

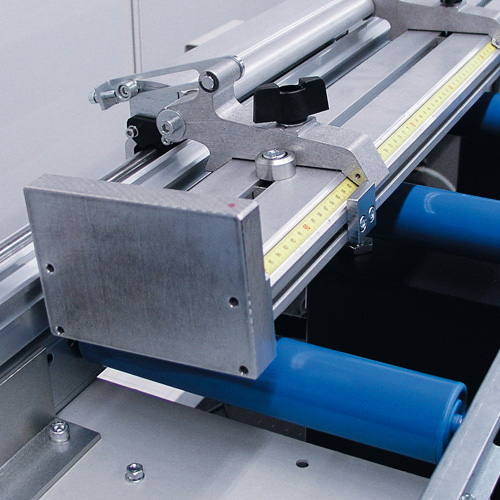

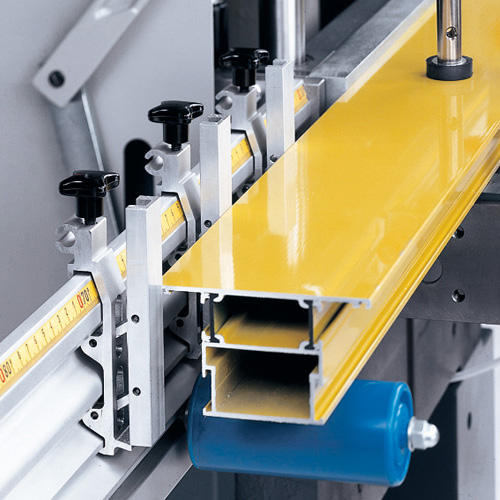

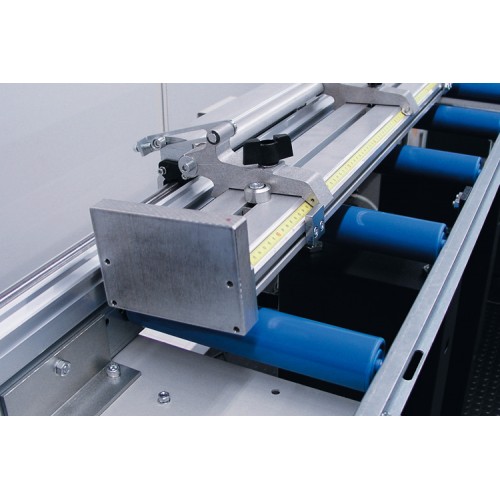

- Infeed with motorised, continuously adjustable gripper

- Lifting function for gap-free loading of the feed magazine

- Profiles are guided on rollers to ensure gentle treatment of the profile and protective film as well as completion of long machining operations without re-clamping

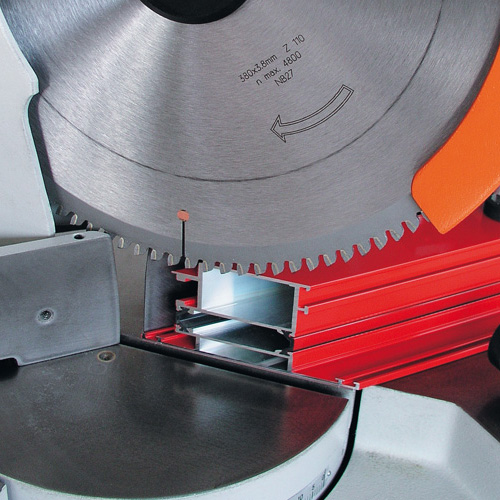

- Simultaneous reinforcement screw driving through external screw driving station

- Internal gripper avoids damaging the profiles

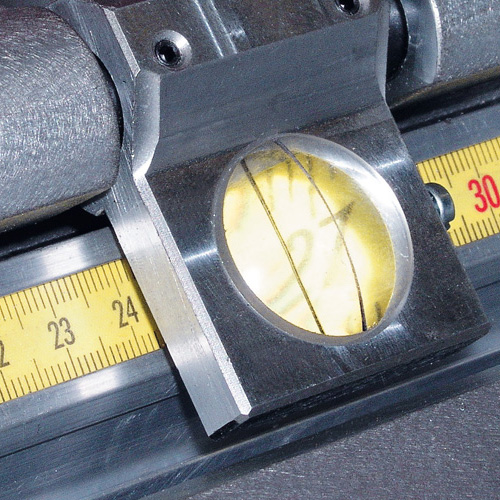

- Integrated measuring sensors for part length monitoring

- Outfeed for parts via discharge table

- Industrial PC with Windows operating system

- Barcode scanner

Technical specifications

- Feed magazine capacity, eleven profile bars

- Part lengths 400 – 4,000 mm

- Profile cross-sections up to 130 x 205 mm W x H

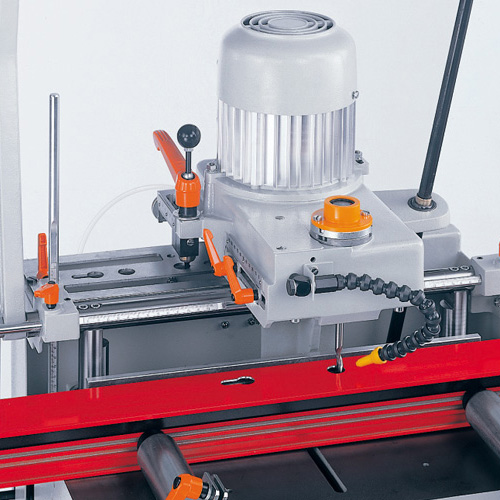

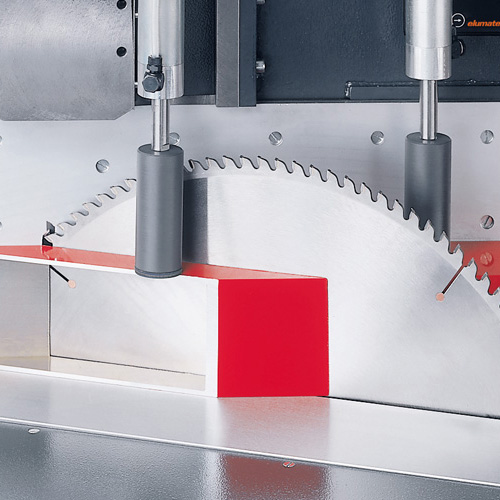

- Capacity for up to 30 machining units

- Routing units with up to 20,000 rpm

- Drilling unit with gear unit delivers 1.2 kW

- Pivoting reinforcement screwdriver unit for screw placement from both sides

Options

- Outfeed for parts via a belt conveyor protects profiles and offers different capacities

- Additional reinforcement screwdriver units for multiple types of screws

- Upending unit for profiles that are difficult to clamp

- Reinforcement screwdriver unit with controlled servo drive for screw tightening with a gentle touch