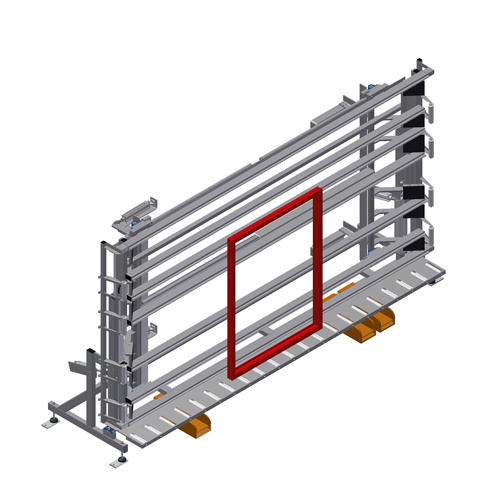

Description

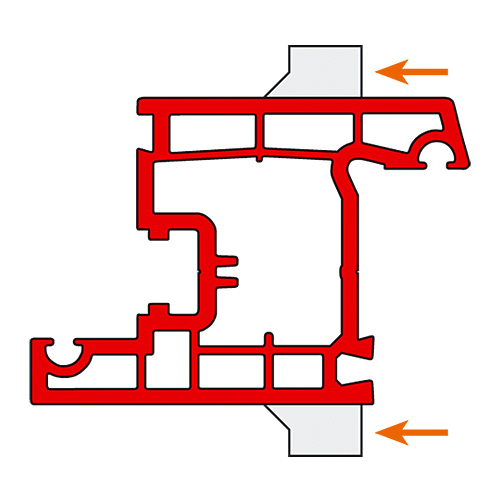

- Simultaneous machining of outer contours and the welding beads on the top and bottom

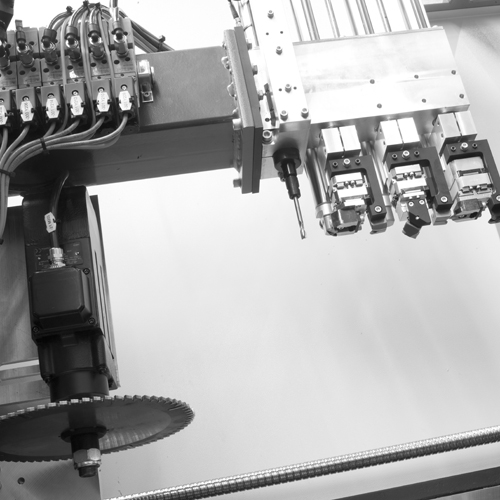

- Four milling cutter positions for freely-configurable cutter sets

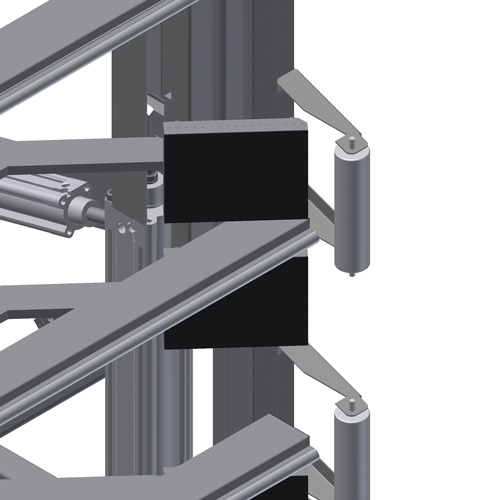

- Optimal groove quality on convex and concave profile surfaces thanks to spring-loaded groove knives

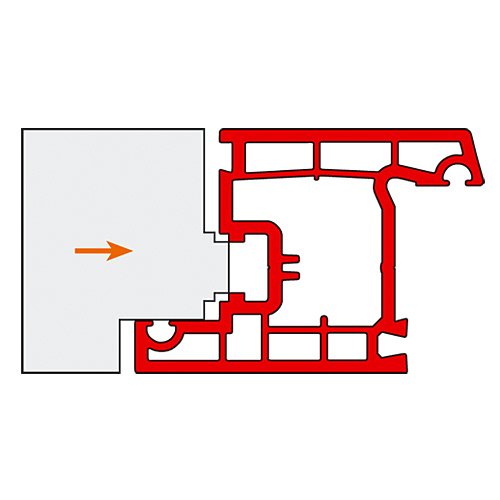

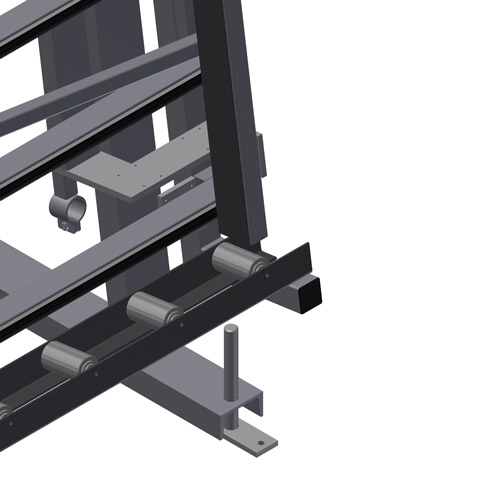

- Adjustable infeed draws even heavy and high profile elements (e.g. entry doors) in accurately and reliably

- No twisting of the profiles thanks to horizontal and vertical profile clamping

- Cutter diameters up to 260 mm possible for profiles with extreme depth dimensions

- Equipped with a unit for blowing off chips as standard, which prevents inaccuracies due to chips becoming stuck

- Versatile due to groove knives and milling cutters which can be switched on individually as well as cutter combinations that can be changed quickly

- Four router spindles for cutter diameters up to a maximum of 260 mm

- Error minimisation through intelligent, automatic profile distinction between frames and sashes at milling positions 1 and 2

Technical specifications

- Maximum frame size is theoretically unlimited

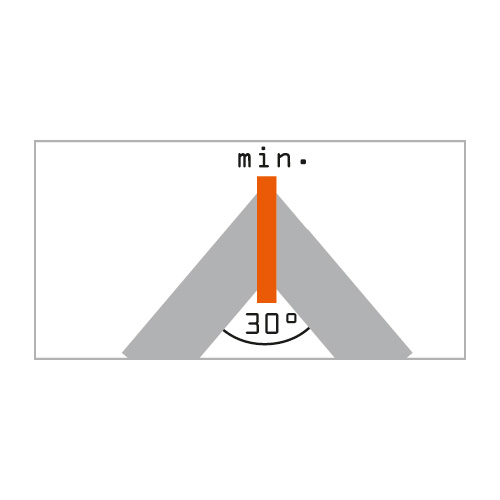

- Min. frame size outer dimension 290 x 290 mm

- Min. frame size inner dimension 160 x 160 mm

- Max. profile height 200 mm

- Profile height min. 25 mm

- Cutting tool diameter 260 mm max.

- Spindle speed 3,200 rpm

- Router spindle diameter 32 mm

- One router spindle for cutter packages up to a height of 200 mm

- Power supply 230/400 V, 3~, 50 Hz

- Power output 2.5 kW

- Compressed air supply 7 bar

- Air consumption per working cycle 100 l

- Length 980 mm, depth 1,700 mm, height 1,670 mm, weight 590 kg