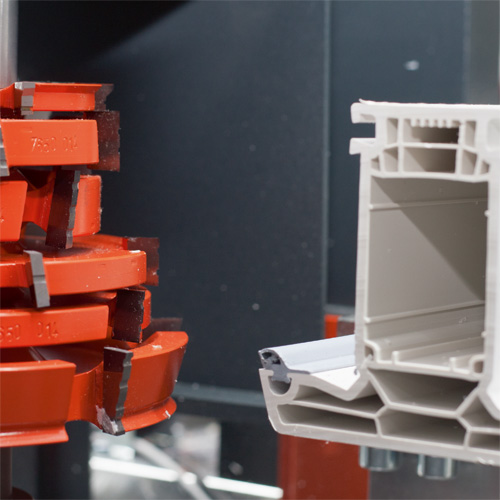

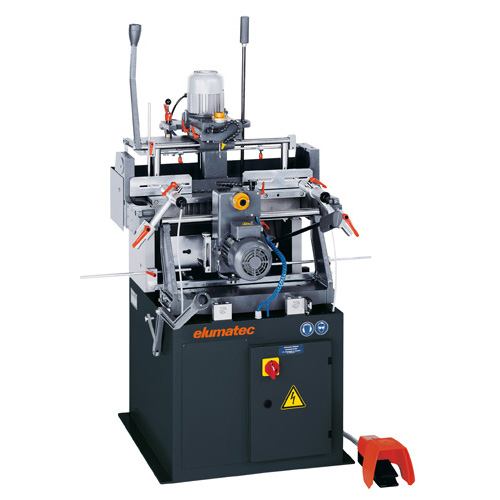

Downstream centre for reinforcement screw driving, drilling and routing cut-to-length profiles for window, door and curtain wall manufacturing with and without steel reinforcement.

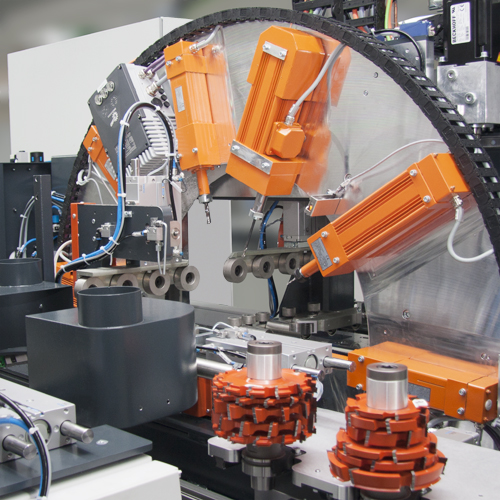

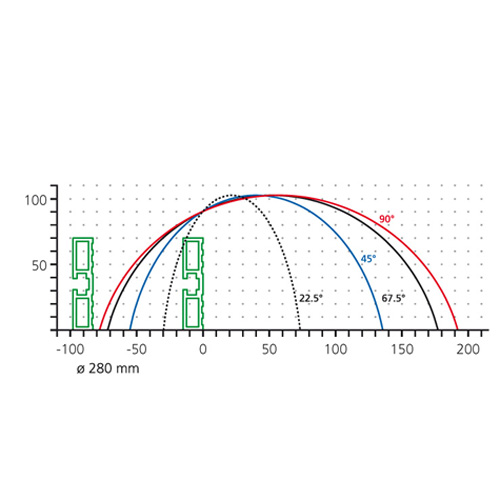

Designed as a ring module with a flexible rotation angle that can deal with all machining positions and all requirements.

- Work sequence as needed, either from the left towards the right or the reverse

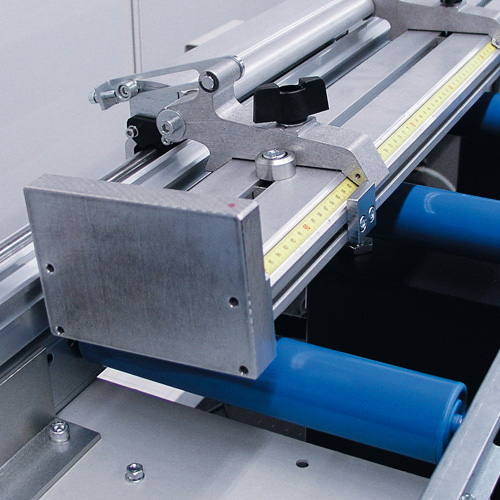

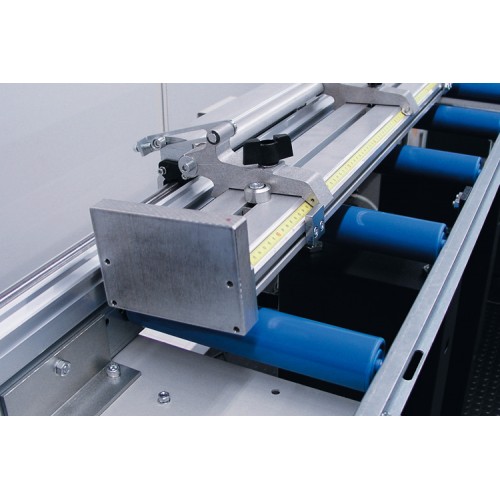

- Outfeed gripper with motorised, continuously adjustable gripper

- Lifting function for gap-free loading of the feed magazine

- Profiles are guided on rollers to ensure gentle treatment of the profile and protective film as well as completion of long machining operations without re-clamping

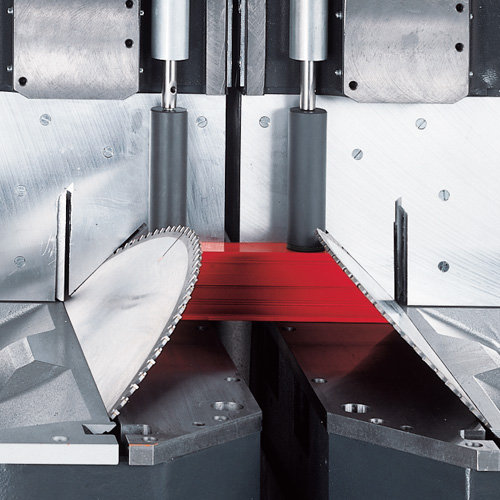

- Optional notching module available with up to four tool positions

- With up to nine frequency-controlled processing motors

- Internal gripper avoids damaging the profiles

- Measuring unit for accurate profile positioning

- Flexible unit configuration, depending on requirements

- Handle drilling unit with gear unit

- Industrial PC with Windows operating system

- Barcode scanner

Technical specifications

- Can be loaded with up to ten profiles

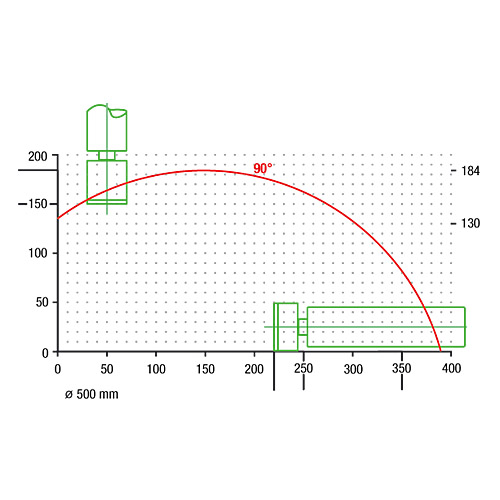

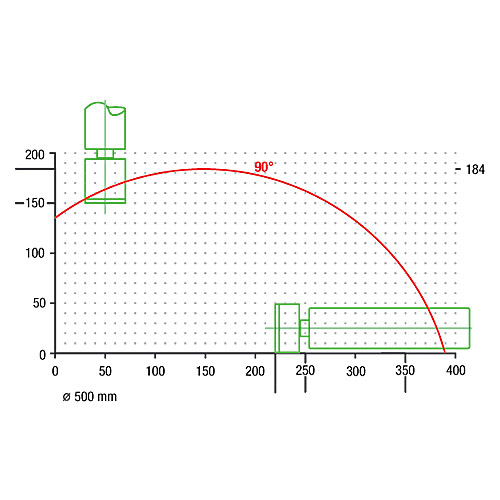

- Part lengths 400 – 4,000 mm

- Drilling unit with gear unit delivers 1.2 kW

- Routing units with up to 20,000 rpm

- Powerful reinforcement screwdriver units with a standard bit holder

Options

- Outfeed for parts using a belt conveyor, plus lifting function for outfeed of the finished profiles with no impact on the automatic process.

- Notching module options

- Frequency-controlled spindle with up to 8,000 rpm

- HSK-F63 standard tool holder

- Tool diameters up to 200 mm

- Automatic tool changer with up to four positions