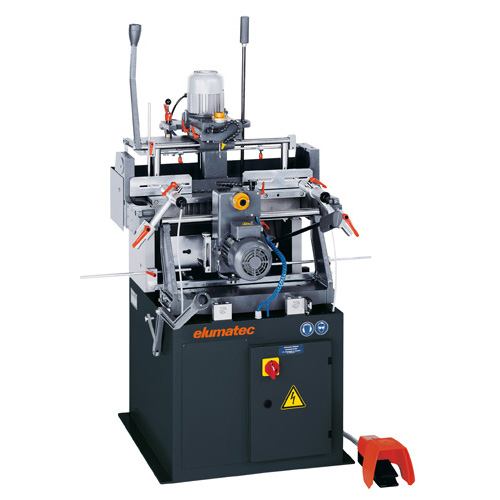

The SBZ 628 series offers ultimate flexibility in both machining and length cutting of aluminium profiles for metal construction and industrial applications. Its production reliability, speed, cost-effectiveness and impressive versatility make the flexible profile machining centre the perfect all-rounder. It allows fully automatic machining of various profile types, such as for windows, doors and curtain walls, using up to eight routing units that can operate freely on the profile cross-section in coordination with patented innovations such as travelling clamps and pivoting grippers.

SBZ 628 S: pass-through system for windows and doors

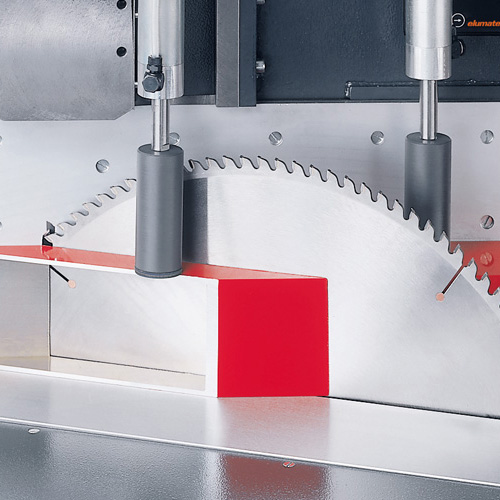

- Four spindles for routing or drilling

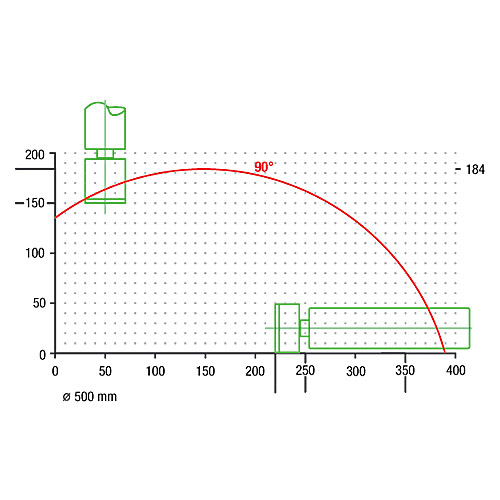

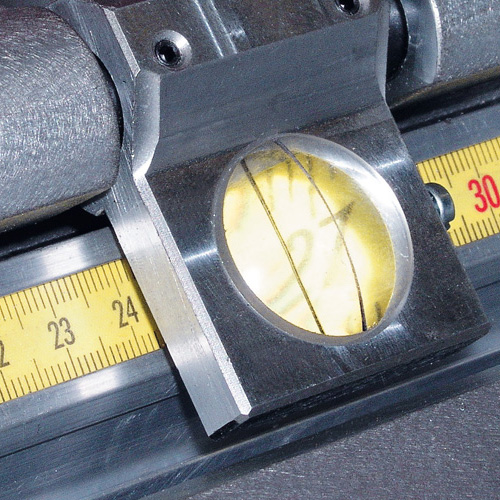

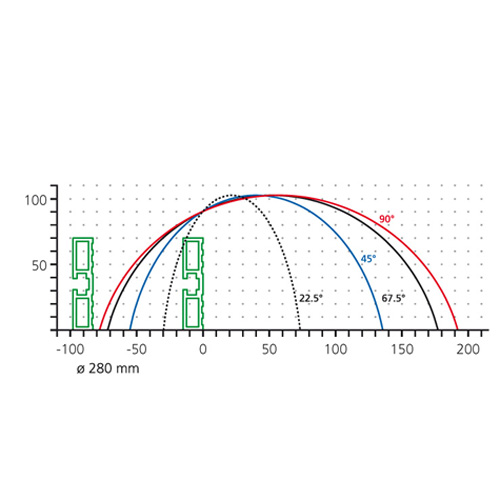

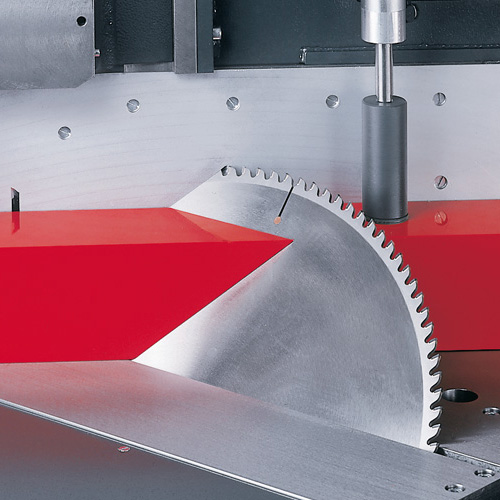

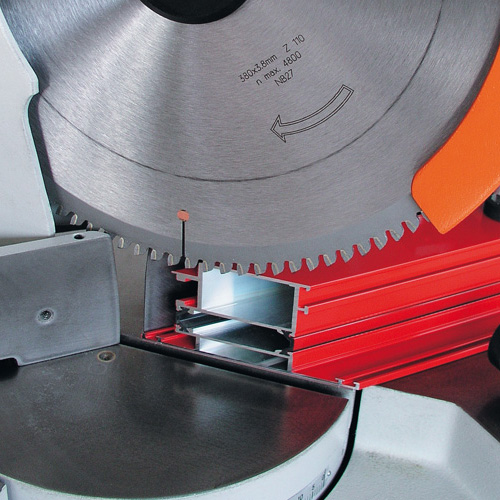

- Separating cuts from -45° to 90° (lead cut), from 90° to 45° (end cut) continuously adjustable

Machine configuration

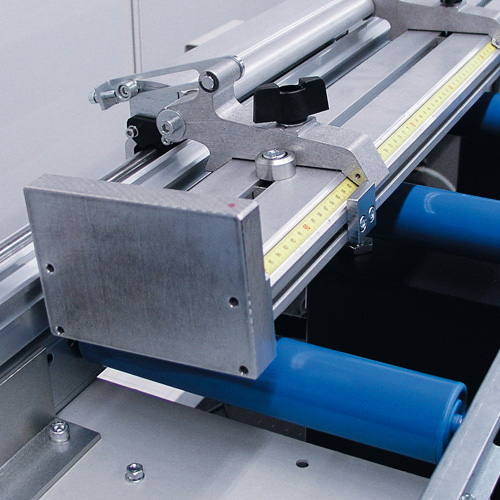

- Left loading magazine for automatic production processes

- The routing spindles can be positioned continuously over 360° on the profile bar, and the cutting angle can be adjusted continuously over 360° for machining profiles in various clamping situations

- A generously dimensioned noise abatement enclosure and the easy-access controls and maintenance elements simplify operation

- Machined profiles are placed gently onto the unloading magazine

- Versions customized to meet specific customer requirements can be designed upon request