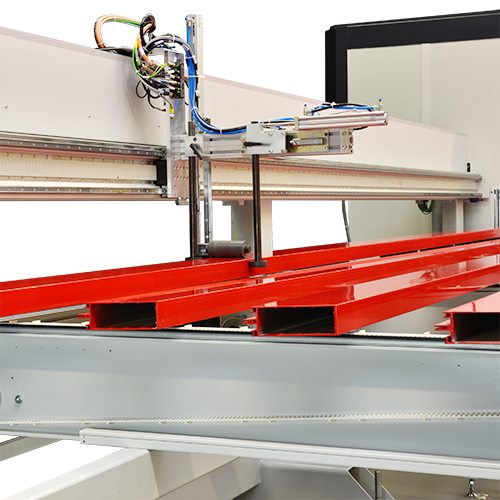

Profile machining centre with loading and outfeed magazine

- Left or right loading magazine for automatic production processes

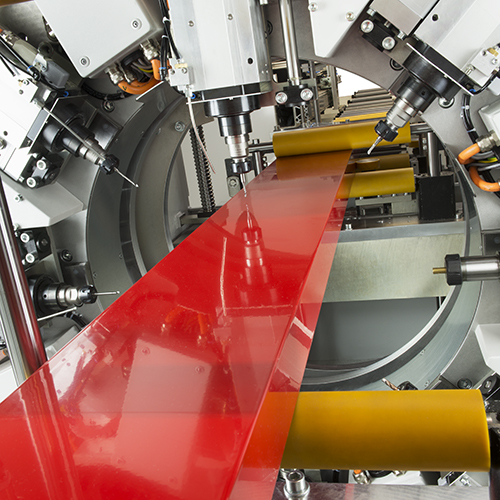

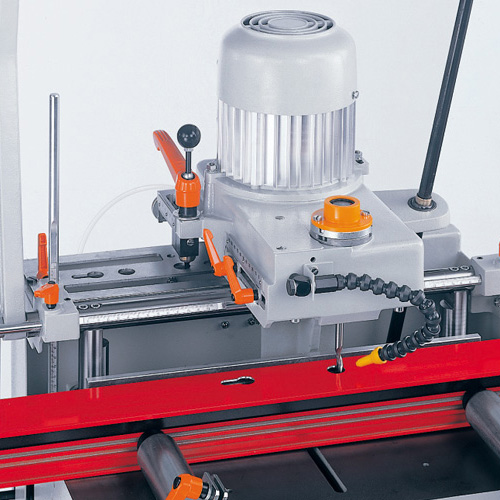

- It is possible to employ up to eight different tools in a single pass thanks to a rotation module

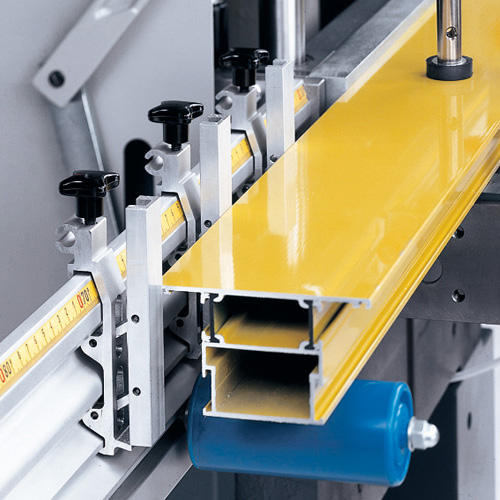

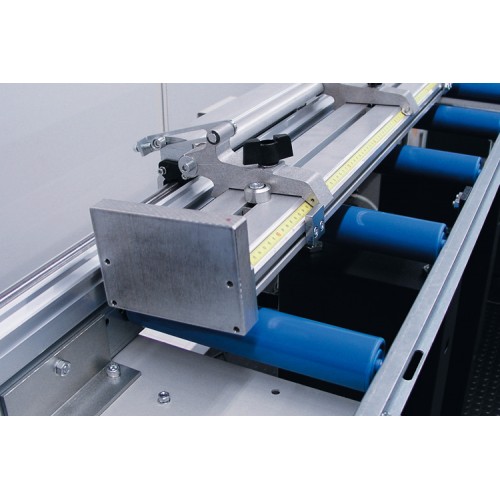

- The patented motorised gripper system, which can be rotated and adjusted vertically and horizontally, moves complex profile cross-sections into position for machining with precision and speed

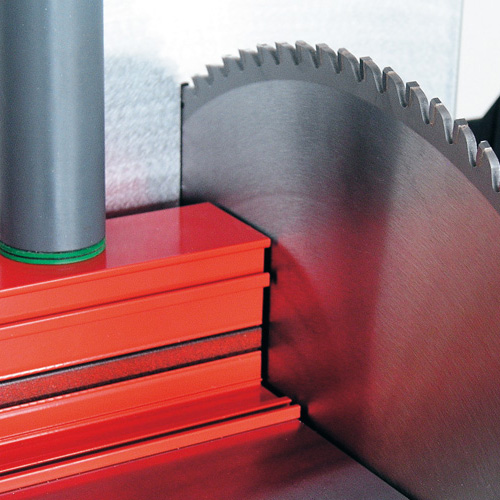

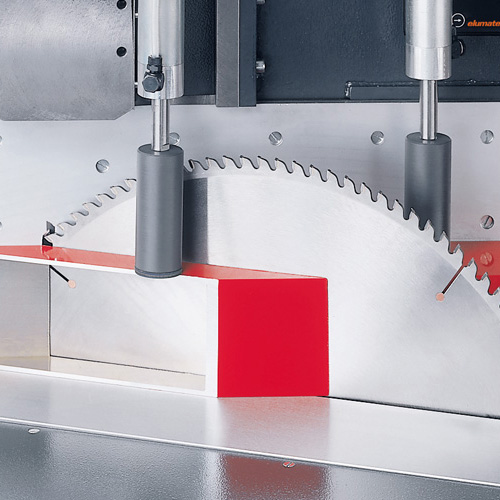

- The router spindle, which can be rotated up to 360°, and the continuously adjustable saw blade allow profiles to be machined in a wide variety of clamping situations

- The generously dimensioned noise abatement enclosure and the easy-access controls and maintenance elements simplify operation.

- During outfeed, the unloading magazine is used to place machined profiles gently onto the outfeed conveyor

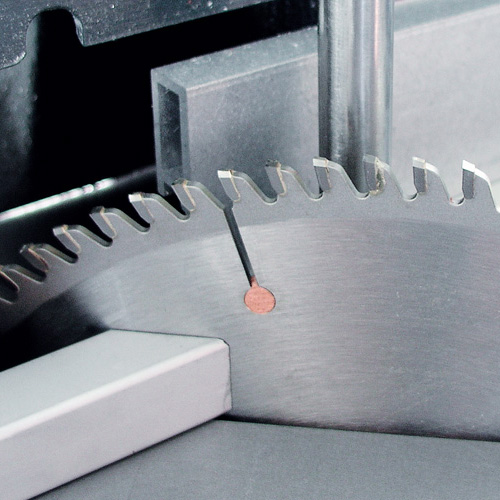

- Machining is performed either “on the fly” using a pusher axis, or while stationary

Technical specifications

- Profile bar length 1,500 – 7,500 mm

- Loading magazine for five or ten profiles (depending on the profile cross-section)

- 4-axis machining module with four router spindles

- Spindle power output 6.0 kW S1 with HSK-C 40 tool holder

- Saw blade, 550 mm

- 4-axis saw unit:

- Power output 5.5 kW

- Travelling range 1,050 x 720 x 400 mm

- Continuously adjustable pivoted cuts between 0° – 360°C

Options

- Two or four additional router spindles

- Horizontal cutting unit with tilting axis

- Saw blade 650 mm

- Replacement roller set

- Residual piece processing from 1,500 mm

- Automatic residual piece measurement

- Label printer

- Cycling mode for machining and cutting short parts

- eluCad (office software package for optimised production management)