Description

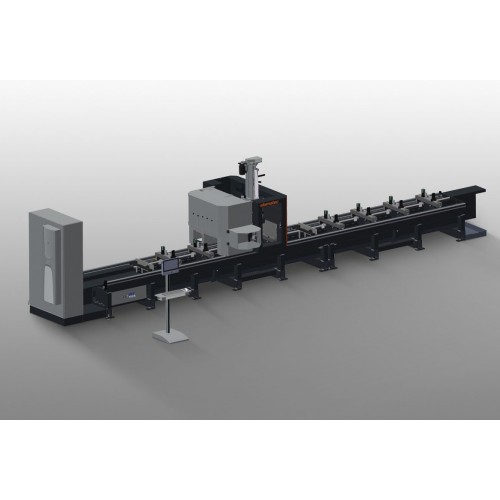

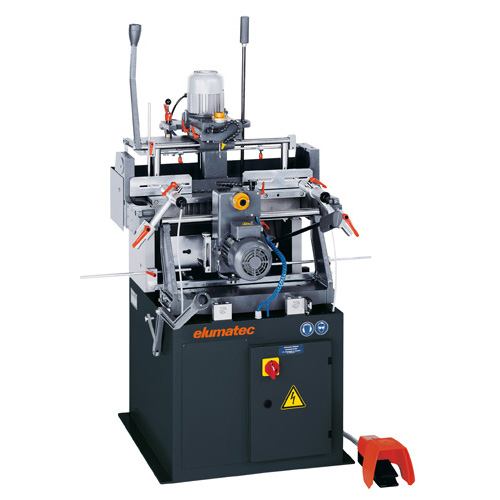

The SBZ 141 4-axis profile machining centre is the latest addition to elumatec’s highly successful SBZ 14x series. The new model comes with high-performance features to round off the product family. The machine bed has once again been made more stable and given a more ergonomic design, while the autonomous clamp positioning is also new. This allows more efficient cycling of the machining steps, which accelerates pass-through times. The hood and the control panel have been redesigned to make operation more efficient.

Advantages at a glance

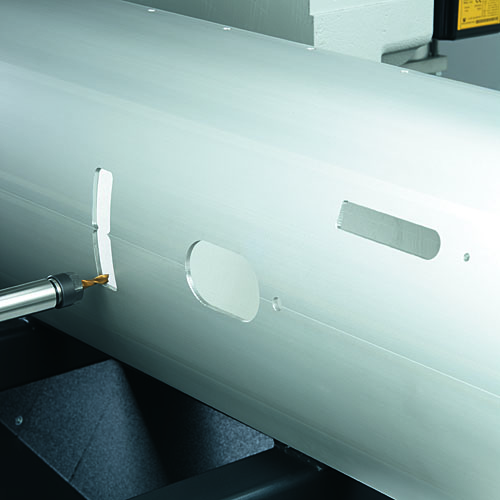

4-axis profile machining centre for economical and efficient machining of aluminium and thin-walled steel profiles

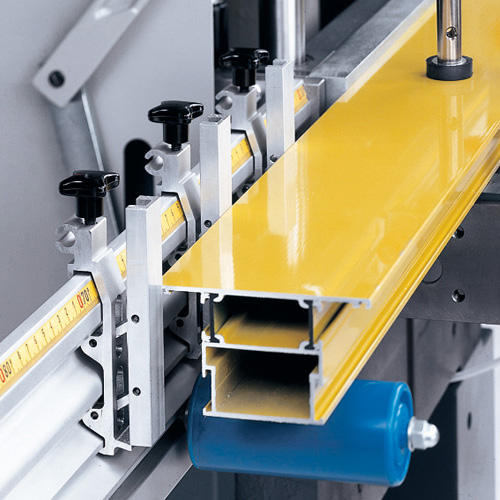

Autonomous clamp positioning enables clamp arrangement during secondary time

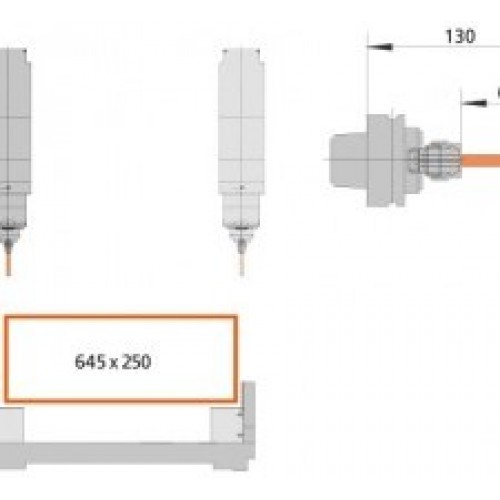

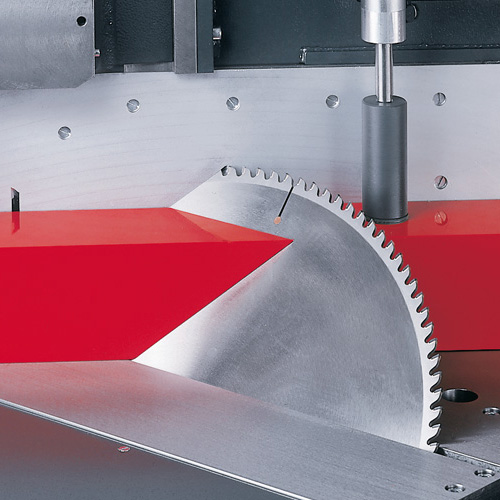

All operations, such as routing, drilling and tapping are performed while the profile bar is stationary to protect the profile surfaces

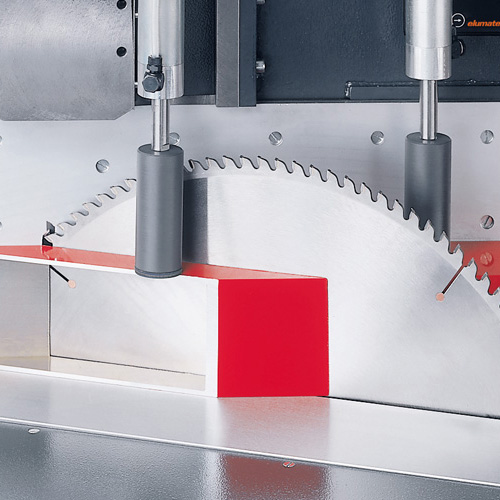

Machining with all tools at angles continuously adjustable from 0° to 180°

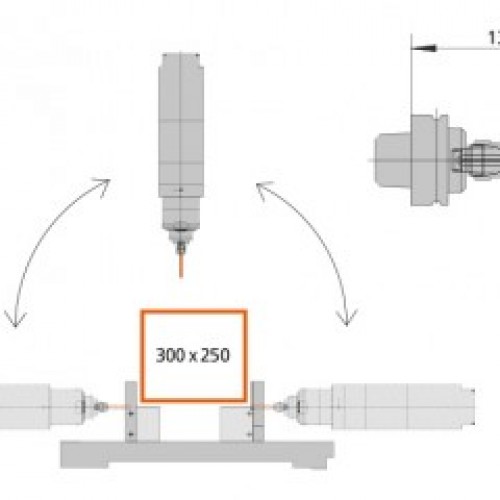

A rotating angle head with two different tools is available for double-bar and end machining (0° – 90° – 180° – 270°) (option)

Technical data

X-axis traverse path 4.200 mm, 7.600 mm, 9.700 mm

Y-axis traverse path 850 mm, Vmax. 65 m/min.

Z-axis traverse path 650 mm, Vmax. 60 m/min.

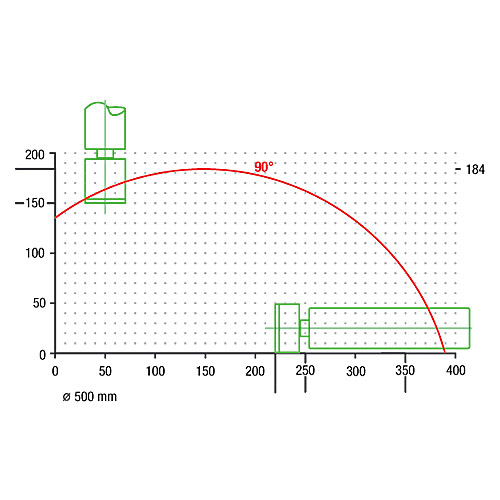

Pivoting angle A-axis, 0° – 180°; freely programmable in 1/10° steps

Max. spindle speed 24,000 rpm

Spindle power output 11 kW, S1

Tool changer for eight tools, additional stationary tool positions on request

Options

Automatic length measurement

Clamping unit accommodates double profile machining

Chips conveyor belt

Barcode scanner

Stationary tool magazine

Angle routing heads

Tool holders

Collet chucks

Collets

Tools

eluCad (office software package for optimized production management)